Matters Needing Attention in Maintenance of Low Temperature Chamber

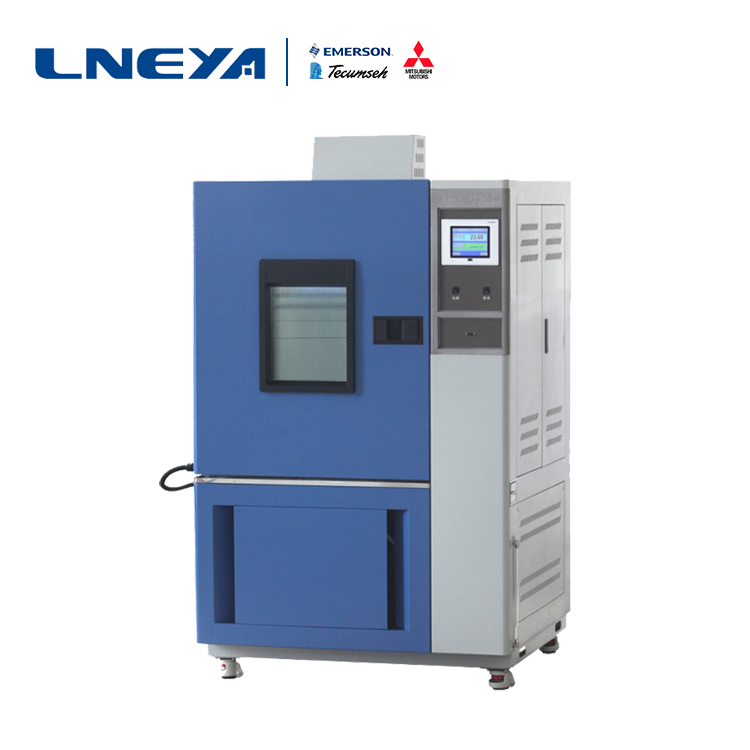

2.The temperature and humidity of the low temperature chamber are the important factors affecting the performance of the instrument. It can cause the corrosion of mechanical parts, reduce the smoothness of metal mirror, and cause the error or performance degradation of mechanical parts of high and low temperature test box. The corrosion of optical components such as gratings, mirrors and focusing mirrors in high and low temperature test boxes results in insufficient light energy, stray light, noise, etc. Even the instruments stop working, thus affecting the life of high and low temperature test boxes, which should be regularly corrected during maintenance.

3. A certain amount of dust will accumulate inside the low temperature chamber after a certain period of use. It is better for the cryogenic testing machine to open the outer cover of the high and low temperature testing box periodically under the guidance of the maintenance engineer or engineer for dust removal. At the same time, the radiators of each heating element are re-tightened to clean the sealing window of the optical box. If necessary, it should be calibrated to clean and lubricate the mechanical part. Finally, it should be restored to its original state and some necessary tests, adjustments and records should be made.

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -