WATER COOLED CHILLERS

Explosion-proof Customized

High Temperature · Low Tempeature · Ultra Low Temperature

Water-cooled chillers are widely used in medical, biological, chemical, and other industries. Due to their heat exchange through water, they are suitable for coating, mechanical processing, rapid cooling, and stable temperature control, without being affected by environmental factors. LNEYA’s water cooled chiller does not require a cooling tower, so it is very simple to install and can be moved according to demand, making it convenient and suitable for situations where there is a lack of water sources without installing a water tower.

LNEYA’s water-cooled chillers can be used for temperature control of various chemical and pharmaceutical reaction processes, as well as temperature simulation of vehicle component quality test and temperature cooling of chip semiconductor manufacturing process.

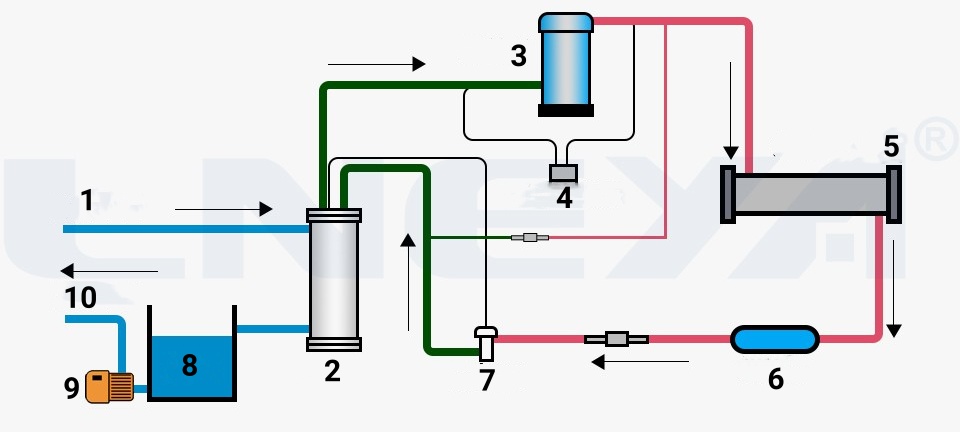

Working Principle

1.Chilled Water Return 2.Evaporator 3.Compressor 4.Pressure Controller 5.Water Cooled Condenser

6. Filter 7.Expansion Valve 8. Water Tank 9.Pump 10.Freezing Water Outlet

Extraction Ulta-low Temp Water Cooled Chillers

|

Model

|

Cooling Capacity

|

Circulation Pump

|

Expansion Tank

|

Power

|

|

LC -25°C~ 5°C

|

12kW~360kW

|

6.6m³/h~50m³/h 2.5BAR

|

100L~1800L

|

12kW~247kW

|

|

LJ -45°C~-10°C

|

6kW~360kW

|

6.6m³/h~50m³/h 2.5BAR

|

50L~1800L

|

102kW~247kW

|

|

LN -60°C~ -10°C

|

6kW~360kW

|

6.6m³/h~50m³/h 2.5BAR

|

100L~1800L

|

14kW~300kW

|

|

LD -80°C~ -30°C

|

4kW~270kW

|

10m³/h~250m³/h 2.5BAR

|

100L~2200L

|

14kW~588kW

|

|

CDLJ -110°C~-50°C

|

2kW~180kW

|

6.6m³/h~50m³/h 2.5BAR

|

50L~1000L

|

14kW~768kW

|

|

LT -120°C~-70°C

|

0.3kW~4kW

|

20L/min0.7BAR~35L/min1BAR

|

|

8.6kW~36kW

|

|

SLJ -110°C~-150°C

|

1.4kW~11kW

|

|

14L~40L

|

5.5kW~14kW

|

Reactor Water Chiller & Thermostat

|

Model

|

Cooling Capacity

|

Heaing Power

|

Circulation Pump

|

Power 220V 380V

|

|

SUNDI -30℃~180℃

|

0.3kW~3kW

|

2kW~3kW

|

10L/min 0.8bar~20L/min 2bar

|

2.9kW~4.5kW

|

|

SUNDI -10℃~200℃

|

1.5kW~15kW

|

2.5kW~15kW

|

20L/min 2bar~75L/min 2.5bar

|

3.6kW~20kW

|

|

SUNDI -25℃~200℃

|

1kW~200kW

|

2.5kW~200kW

|

20L/min 2bar~600L/min 2.5bar

|

4kW~260kW

|

|

SUNDI -25℃~300℃

|

1kW~200kW

|

2.5kW~200kW

|

20L/min 2bar~600L/min 2.5bar

|

4kW~260kW

|

|

SUNDI -45℃~250℃

|

0.45kW~200kW

|

3.5kW~200kW

|

35L/min 2bar~600L/min 2.5bar

|

6.5kW~280kW

|

|

SUNDI -45℃~300℃

|

0.9kW~25kW

|

5.5kW~25kW

|

35L/min 2bar~150L/min 2.5bar

|

9.5kW~38kW

|

|

SUNDI -60℃~250℃

|

2.5kW~60kW

|

0.25kW~60kW

|

20L/min 2bar~250L/min 2.5bar

|

5kW~95kW

|

|

SUNDI -70℃~250℃

|

0.4kW~15kW

|

2.5kW~15kW

|

20L/min 2bar~110L/min 2.5bar

|

5.2kW~28kW

|

|

SUNDI -80℃~250℃

|

0.3kW~80kW

|

3kW~80kW

|

20L/min 2bar~400L/min 2.5bar

|

7.5kW~150kW

|

|

SUNDI -90℃~250℃

|

0.2kW~80kW

|

3kW~80kW

|

20L/min 2bar~400L/min 2.5bar

|

8kW~170kW

|

|

SUNDI -100℃~135℃

|

0.45kW~80kW

|

3.5kW~80kW

|

35L/min 2bar~400L/min 2.5bar

|

12kW~200kW

|

Semiconductor Testing Water Chiller Heater

|

Model

|

Heating Power

|

Refrigerating Output

|

Temp. control Accuracy

|

Power

|

Circulation Pump

|

|

TES -45℃~250℃

|

2.5kW~25kW

|

0.25kW~25kW

|

±0.3℃

|

6kW~36kW

|

20L~150L/min2.5bar

|

|

TES -85℃~200℃

|

2.5kW~25kW

|

0.25kW~25kW

|

±0.3℃

|

6.5kW~50kW

|

20L~150L/min2.5bar

|

|

TES -60℃~200℃

|

15kW~60kW

|

3kW~60kW

|

±0.3℃

|

28kW~105kW

|

110L~300L/min2.5bar

|

Vehicle/Battery Testing Water Chiller Heater

|

Model

|

Heating Power

|

Cooling Capacity

|

Temp. control Accuracy

|

Power

|

|

KRY -40℃~+100℃

|

5.5kW~38kW

|

1.2kW~60kW

|

±0.5℃

|

12kW~82kW

|

|

KRY 0℃~+100℃

|

2.5kW~38kW

|

1.8kW~60kW

|

±0.5℃

|

6.5kW~50kW

|

|

KRY -25℃~+100℃

|

5.5kW~25kW

|

2.8kW~38kW

|

±0.5℃

|

11kW~45kW

|

customized indoor& outdoor chillers

Applications

- Plastic industry: Precisely control the temperature of various plastic granulation molds, reduce beer forming cycle time, and ensure stable product quality.

- Electronic Industry: Stabilize the molecular formula of electronic components in production lines, improve the standard rate of electronic components, apply in the field of ultrasonic cleaning, and reasonably avoid the damage caused by expensive detergent evaporation and evaporation.

- Electroplating field: controlling electroplating temperature, improving the relative density and smoothness of electroplated parts, shortening electroplating cycles, improving productivity, and improving product quality.

- Mechanical Engineering: Control the working pressure and oil temperature of the steam pressure system software, stabilize the water temperature and steam pressure, increase the use time of oil, improve the lubrication efficiency of mechanical equipment, and reduce wear.

- Engineering construction industrial production: providing frozen water for concrete, making the molecular formula of concrete suitable for the main purpose of engineering construction, and reasonably improving the strength and ductility of concrete.

- Vacuum coating: Control the temperature of the vacuum coating machine to ensure the high quality of the plated parts.

- Chemical and pharmaceutical industries: In the medical industry, the key is to control the temperature of hair alcohol drugs. Pharmaceutical manufacturing enterprises should flexibly use chiller equipment, fully leverage its advantages, strengthen technological innovation, improve the cost-effectiveness of chillers, and better serve projects in the pharmaceutical industry.

- Laser industry: used for laser marking machines, laser engraving machines, laser welding machines, laser inkjet printers, laser cutting machines and other laser processing equipment, accurately controlling the temperature required by laser equipment to ensure the normal operation of laser equipment.

Accessible Equipments

1.Reactor 2.Vacuum Chamber 3.Experimental Instruments 4.Microchannel

1.Semiconductor 2. Mechanical assembly 3.Dryer 4.Evaporator

Accept Customized Outdoor Chiller and Indoor Chiller

Outdoor Chiller

Indoor Chiller

Low Temp/Normal Temp Chillers (Biochemistry Pharmaceutical Process)

Temperature Control :-5℃~-150℃

Temperature control for Various reactors, distillation or extraction systems, laboratories, research institutes, chemical, pharmaceutical, petrochemical, biochemical, medical, hospital, research and development workshops, semiconductor testing, aerospace, biology.

Dynamic Temperature Control Systems (Biochemistry Pharmaceutical Process)

Temperature Control :-120℃~350℃

Temperature control for high pressure reactor;Double-layer glass reactor;Double-layer reactor;Microchannel Reactor;Distillation system;Material aging test;Vacuum chamber etc.

Control Temperature Control Flow Systems(Vehicle/Battery Pack Test)

Temperature Control: -40℃~100℃

Temperature simulation for vehicle quality test: battery life test, fuel injector/motor test bench, airbag test, component test bench, etc. It can simulate the external environmental conditions in the climate chamber or replace the internal system, which can create the necessary actual temperature conditions for the test bench.

Cooling Heating Systems (Semiconductor Production)

Temperature Control: -85℃~250℃

Suitable for semiconductor process wet washing, photolithography, etching, chemical meteorological deposition, physical meteorological deposition, and the electronics industry (photolithography process)

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -