Temperature control during new energy vehicle battery test

With the continuous implementation of energy saving and emission reduction policies, new energy power batteries are also continuously encouraged to develop, and liquid cooling systems have become an inevitable trend for new energy vehicles. The original new energy vehicles can no longer solve the problem of battery heat dissipation by using air-cooled heat dissipation. The advantages of the liquid cooling system of Lneya’s KRY high and low temperature coolant tester are fast cooling rate, good temperature uniformity, and simple fluid (temperature and flow) control.

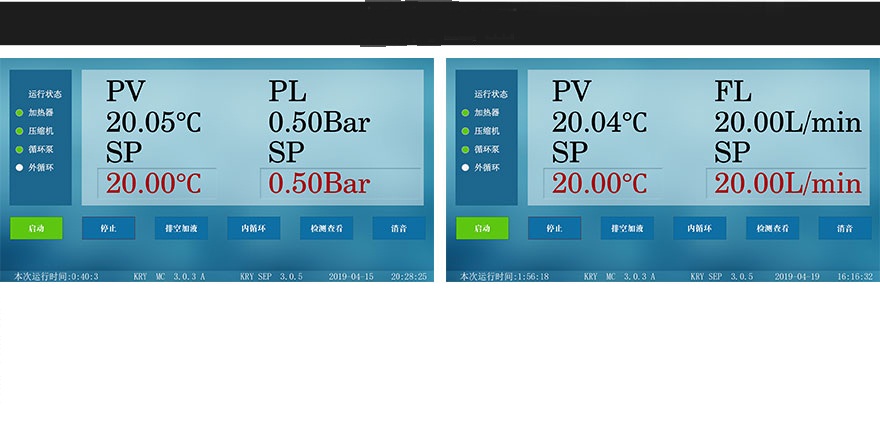

KRY high and low temperature coolant tester combines high and low temperature test box and antifreeze cooling heating flow system to provide high energy and low temperature antifreeze and antifreeze flow, pressure control and 1000L high and low temperature test environment for new energy vehicle battery packs. It can achieve battery packs and other tests in a high environment, and provide high temperature, low temperature, flow control, and pressure requirements for battery packs. The temperature achieves -40 ℃ ~ 130 ℃ antifreeze temperature, antifreeze flow control 2 ~ 20L / min, and the environment box provides -45 ℃ ~ 100 ℃.

Lneya follows the needs of the country in the development of new energy vehicles, and set up a team to specifically develop high and low temperature coolant testers for new energy vehicles. New energy vehicle battery high and low temperature testers and cooling systems for battery testing. The technology is advanced and mature. Used by well-known domestic new energy vehicle companies.

At present, the battery pack (PACK) liquid-cooled heat dissipation system operates relatively rarely, and vehicle manufacturers need to know the following data:

A), the reasonable temperature of the battery pack is 10 ℃ -30 ℃, the liquid cooling system may reach -30 ℃ in low temperature weather, the battery pack itself has a heating block to pre-heat before starting to play a thermal protection function, when the battery temperature exceeds When the temperature is above 30 ℃, the temperature needs to be lowered by -30 ℃ liquid cooling system. To ensure that the battery temperature is controlled within the range of 10 °C-30 °C, and the diameter of the automobile liquid cooling system is fixed, then the pressure needs to be adjusted to control the flow. By analogy, as the temperature of the automobile coolant changes, the flow rate and pressure of the coolant must be changed to ensure the battery temperature.

2.) When the temperature is high, the temperature of the car coolant and battery pack may reach above 50 °C. What is the charge and discharge condition of the battery pack? How does the cooling capacity of the entire vehicle cooling system (air-conditioning space in the vehicle, battery pack, electric drive, and engine liquid cooling system) match so that the vehicle’s thermal management can achieve a rapid balance. Let the vehicle performance and safety reach a reasonable range. The above data needs to be provided by our liquid cooling thermal test platform.

Lneya’s KRY high and low temperature coolant tester has a self-diagnostic function; phase sequence phase failure protector, freezer overload protection; high pressure pressure switch, overload relay, thermal protection device and other safety protection functions.

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -