Which processes of ultrafine material enterprises require cooling water chillers?

Ultrafine material enterprises often require precise temperature control during the production process to ensure the quality of the product and the stability of the production process. Water chillers play a key role in multiple processes of ultrafine material enterprises.

The following are the main applications of water chillers in ultrafine material enterprises:

1.Raw material pretreatment:

- Drying process: During the drying process of ultrafine materials, the temperature of the drying equipment needs to be precisely controlled to avoid over-drying of the raw materials or excessive moisture content.

- Mixing process: When mixing raw materials, the temperature of the mixing equipment may need to be controlled to ensure that the raw materials are mixed evenly.

2.Preparation process:

- Grinding process: During the grinding process, due to the heat generated by high-speed rotation and friction, a water chiller is required to control the temperature of the grinding equipment to ensure the quality of the material.

- Spray drying: During the spray drying process, the temperature in the drying tower needs to be precisely controlled to ensure the particle size distribution and dryness of the powder.

- Solvent evaporation: When using the solvent evaporation method to prepare ultrafine materials, the temperature of the evaporator needs to be controlled to ensure complete evaporation of the solvent without destroying the material structure.

3. Synthesis process:

•Chemical reaction: The synthesis of many ultrafine materials requires precise temperature control to ensure that the reaction proceeds as expected, such as in processes such as chemical vapor deposition (CVD) or hydrothermal synthesis.

•Polymerization reaction: When synthesizing polymer-based ultrafine materials, the temperature of the reactor needs to be controlled to ensure the molecular weight distribution and degree of polymerization.

4. Post-treatment process:

•Washing process: When washing ultrafine materials to remove residual solvents or impurities, the temperature of the washing equipment needs to be controlled.

•Heat treatment: During the heat treatment process, the temperature of the heating furnace needs to be precisely controlled to improve the crystallinity or structure of the material.

5. Performance test:

•Thermal performance test: When testing the thermal properties of ultrafine materials, a cooling water chiller is required to control the temperature of the test environment to ensure the accuracy of the test results.

•Thermal cycle test: When simulating the performance of the material under different temperature conditions, the temperature change needs to be precisely controlled.

6. Packaging process:

•Encapsulation material curing: When curing the encapsulation material, the temperature of the curing furnace needs to be controlled to ensure the performance of the material.

Temperature control range:

- Low temperature range:

- Low temperature cooling: For processes that require low temperature cooling, such as certain chemical reactions or material synthesis processes, it may be necessary to control the temperature close to or below 0°C.

- Ultra-low temperature cooling: In some special cases, lower temperatures may be required, such as -20°C to -80°C, for specific material processing or research.

2. Medium temperature range:

- Normal temperature cooling: Many ultrafine material processing processes require the temperature to be controlled near room temperature, such as 20°C to 25°C.

- Mild heating: In some cases, the temperature needs to be controlled at a level slightly above room temperature, such as 30°C to 40°C.

3. High temperature range:

- High temperature cooling: For processes that require higher temperatures, such as certain heat treatment processes, it may be necessary to control the temperature at 50°C to 100°C.

- High temperature heating: In some synthesis processes, higher temperatures may be required, such as 100°C to 200°C or higher.

In summary, water cooling units play an important role in many processes of ultra-fine material enterprises, ensuring the temperature control accuracy in the production process and improving product quality and production efficiency. Through precise temperature control, the physical and chemical properties of ultra-fine materials can be well controlled, thus meeting the performance requirements of the final product.

Industrial Water ChillersChilled Water Systems

- MORE

LN -60°C~ -10°C

适用范围 Product Features 产品参数 Product Parameter 行业应用 APPLICATION 航空航天材料|试验装置控温解决方案 在航空航天领域,材料的性能直接关系到飞行器的安全、可靠性和…

- MORE

LJ -45°C~ -10°C

Fast cooling and low cooling temperature -5~-150°C Water Cooling LNEYA specializes in the production of single-fluid cryogenic chillers. The refrigeration temperature ranges from -150°C to -5°C, which can mee…

- MORE

LD -80°C~ -30°C

1.Temperature ranges from -5℃ ~ -150℃, can meet different temperature2. Famous brand semi-closed piston compressor, semi-closed bipolar piston compressor, semi-hermetic screw compressor, main brand are BOCK. Bitzer, Cop…

- MORE

SLJ -110℃~-150℃

1.Temperature ranges from -5℃ ~ -150℃, can meet different temperature2. Famous brand semi-closed piston compressor, semi-closed bipolar piston compressor, semi-hermetic screw compressor, main brand are BOCK. Bitzer,…

loading…

已经是到最后一篇内容了!

- MORE

LT -45℃~30℃

LOW TEMPERATURE COOLING CIRCULATOR For fast liquid cooling 1. Can use ethylene glycol mixed with water for circulating refrigeration, saving resources 2.Circulating pipeline design, prolong t…

- MORE

LT 10℃~30℃

Saving water resources & circulating cooling 1. Can use ethylene glycol mixed with water for circulating refrigeration, saving resources 2.Circulating pipeline design, prolong the use time of circulating …

- MORE

LT -25℃~30℃

Rapid refrigeration using imported brand semi-enclosed piston compressor, semi-enclosed piston two-stage compressor, semi-enclosed screw compressor 1. Can use ethylene glycol mixed …

loading…

已经是到最后一篇内容了!

Related recommendations

-

Heating and cooling cycle machine maintenance boot operation instructions

378When users choose the heating and cooling cycle machine, they often have to choose the right conditions for their own work, and their knowledge of maintenance and start-up also needs our attention. After the installation of the heating and cooling...

View details -

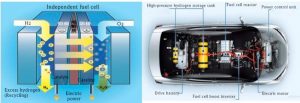

Cooling simulation system for battery pack extreme performance test

404With the development of technology, pure electric vehicles are becoming more and more common, but pure electric vehicles are difficult to get a better solution in terms of cruising range, charging speed, and pollution after battery waste. This mak...

View details -

Lneya Semiconductor High Precision Temperature Control System Description

405Semiconductor high-precision temperature control systems are currently produced in the semiconductor industry with highly complex performance. Here is a description of the semiconductor high-precision temperature control system. Along with large-s...

View details -

Which industries are applicable to semiconductor device testing?

439Semiconductor device testing is used in many semiconductor industries. So, how much do you know about semiconductors and conductors for semiconductor device testing? The properties of this substance are still recommended to the user. In general, s...

View details

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -