News

Why can ethylene glycol chillers be used for polymerization and coupling reactions

1. Polymerization heatingGenerally, the raw materials ofpolymerization reaction are some flammable solvents, and heating up quickly maycause local temperature to be too high and cause accidents. Everypolymerization reaction has its proper reaction temperature. If the temperatureis changed outside, the reaction efficiency will be reduced, and thepolymerization reaction will release more reaction heat. Changing the propertemperature will be immeasurable, especially in industrial productio...

View details

Ways to make ultra-low temperature circulating chillers more energy-efficient

In modern times, environmental protectionand energy saving is the development theme, so is the industrial chiller. Then,how to improve your industrial chiller to be more energy conservation? First, to prevent and reduce the pipescaling of ultra low temperature recirculating chillers is for enhancing theheat transfer efficiency of condenser and evaporator. If the make-up water is treated badly,calcium carbonate and magnesium carbonate produced by calcium bicarbonate andmagnesium bica...

View details

Detailed Introduction of Air Cooled Chiller Equipment

LNEYA refrigeration has accumulated over 10years of cooling supporting application experience. According to differentapplication fields and service conditions, it has developed a variety of typesof cooling chillers, including air cooled chillers and water cooled chillers,which can well meet the needs of equipment cooling. The heat dissipation deviceof air cooled chiller is a built-in fan, which mainly has three interrelatedsystems: refrigerant circulation system, water circulation...

View details

The Main Application Areas of Air Cooled Chillers

Inthe domestic and international industrial water chiller market, our most commonindustrial water chiller equipment can be roughly divided into two differenttypes, one type is industrial air cooled chiller, the other type is industrialwater cooled chiller. Judging from the current penetration rate of chillers inthe industrial market, there is more demand for industrial air cooled chillersand a wider range of applications. So, under normal circumstances, in whichindustries do air cooled...

View details

How to maintain the lubrication system of water-cooled chillers

Medium-sized water cooled chiller,refrigeration temperature range from -80 ℃~ -30℃, safe,reliable, rapid cooling for the liquid, widely used in petrochemical, medical,pharmaceutical, biochemical and freeze-dried, military and other high-tech industries. When the water cooled chiller is below 80℃ ~ 30℃ below zeroin the running system, people pay more attention to refrigerator, frozen watercycle system and electric control system, so the lubrication system is oftenoverlooked. However, t...

View details

Introduction to typical applications of refrigeration and heating thermostats

The refrigeration and heating thermostat is a high and low temperature temperature control system commonly used in the chemical industry. It can refrigerate and heat reactors, reactors, fermentation tanks, extraction, and distillation. How is it done when supporting these for temperature control? 1. Practical application of reaction kettle with cooling and heating thermostat The reaction kettle is a common equipment in the chemical, scientific research, and laboratory reaction process. Gener...

View details

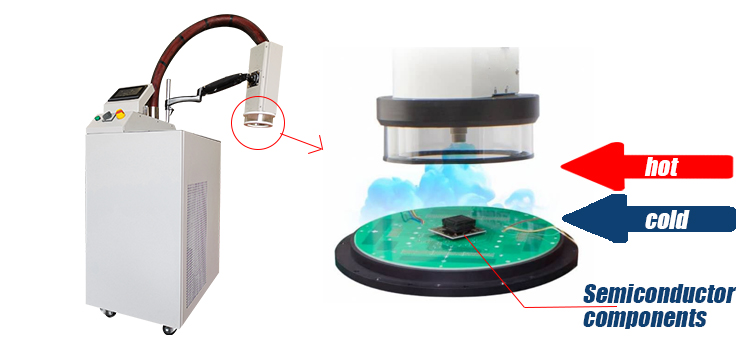

The influence of the evaporator of the semiconductor thermostat on the refrigeration effect

Different models of semiconductor thermostat equipment have different options for evaporation. According to different models, the choice of evaporator is different. For example, box-type semiconductor thermostat equipment uses water tank coil type evaporator; open semiconductor thermostat equipment and screw type semiconductor thermostat equipment use shell-and-tube evaporator ; For acid and alkali resistant semiconductor thermostat equipment, titanium tube evaporator or stainless steel plate...

View details

How to complete the temperature control equipment for the isolation reactor?

The reactor is a commonly used reactor in pharmaceutical and chemical production. The isolation reactor temperature control equipment is realized by controlling two doors, namely the heating water valve and the cooling water valve. The mixing of the mixer makes the material uniform, improves the heat conduction speed, and Make the temperature uniform. The temperature of the isolation reaction kettle is controlled in the heating stage, open the heating water valve, and pass heating water to th...

View details

Small coup to deal with ice blockage of high and low temperature liquid circulating chillers

In the operation of high and low temperature liquid circulating chillers, ice blockage is a relatively common fault. Based on the experience of relevant manufacturers, we have specially compiled relevant tips for dealing with ice jams. In the pipeline of the high and low temperature liquid circulating chiller, if ice blockage occurs, it is recommended to replace the damaged pipe section and repair the missing spot welding first, and redo and tighten the loose threaded joint. In order to ensu...

View details

Different functions of reactor cooling and heating chiller on temperature

The cooling and heating chiller of the reactor is a kind of refrigeration machine, because its main component uses a screw compressor, which can be called the low-temperature chiller of the reactor by its name, and is widely used in industrial production such as electronics manufacturing. Different functions corresponding to different temperatures: The reactor cooling and heating chiller will generally generate heat due to the action of current during operation, and excessively high temperat...

View details LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -