News

How to choose low temperature and high temperature simulation equipment for material aging test?

Material aging testing is used in many industries, but how to choose high-quality low-temperature and high-temperature simulation equipment is very critical, because temperature plays an indispensable and important role in the testing process. LNEYA, as a professional manufacturer of low-temperature and high-temperature simulation equipment for manufacturing material aging test, gives some suggestions to people in related industries to choose a more accurate low-temperature and high-temperatu...

View details

Chemical cooling and heating system – dynamic temperature control system manufacturer

In the pharmaceutical and chemical industries, cooling and heating system are widely used. As the developing of internet, many enterprises compete fiercely. The following will introduce the benefits of the LNEYA chemical cooling and heating system - dynamic temperature control system and what are the safe options.Price is not the main factor for users to choose the chemical cooling and heating system - dynamic temperature control system. The main factor of choice is the suitable temperature t...

View details

Benefits of using heating and cooling equipment in the laboratory

Laboratory heating and cooling equipment (also known as: cold and heat integrated machine, refrigeration and heating cycle device) is a device that integrates cooling and heating, heating and cooling can be quickly converted, and the same medium (thermal oil) is used The medium has improved the current status of heating and cooling that require two different instruments to complete.This equipment belongs to the high and low temperature oil bath external circulation device. Through data progra...

View details

The role of temperature control system TCU in chemical and pharmaceutical reactor

The temperature control of the reaction kettle in drug research and development and chemical experiments, as well as the temperature control in small-scale experimental production and industrial production processes, require highly dynamic temperature control systems. When controlling the temperature of the reaction kettle, it is necessary to quickly and efficiently compensate for the absorption and exotherm of the chemical reaction. Many reactors mix or chemically react materials, often acco...

View details

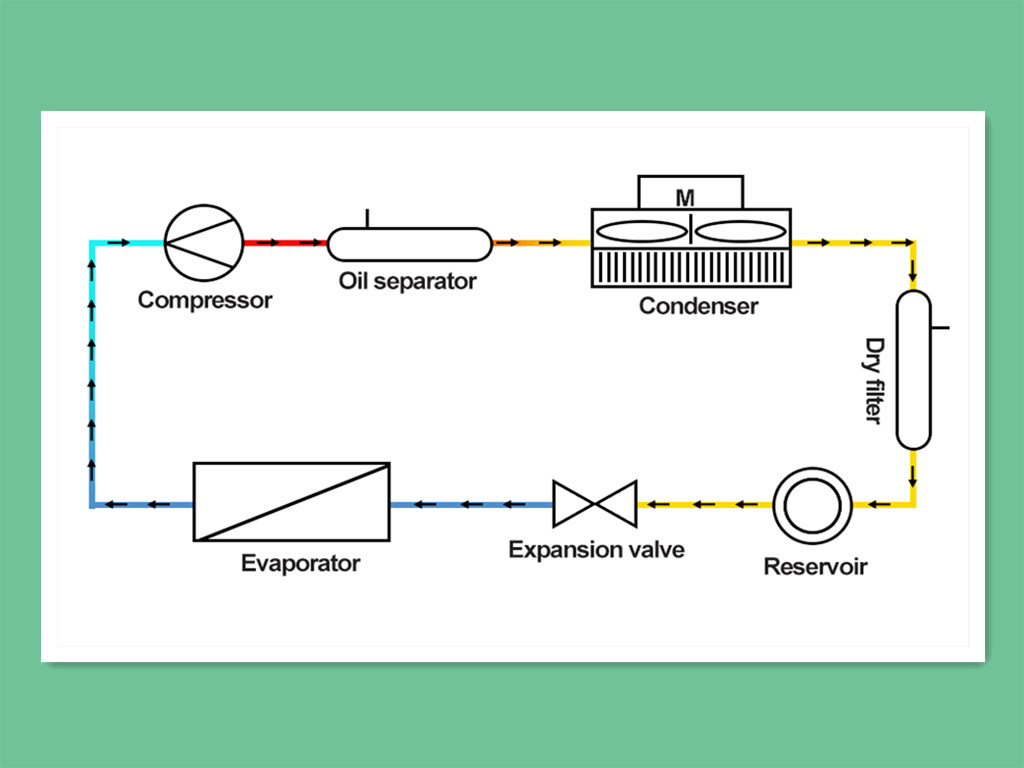

What are the causes of corrosion in industrial chillers / water chillers?

Industrial chillers are now widely used in various industries, but as they become more and more widely used, many problems slowly emerge. Corrosion problems are also relatively common. Because everyone does not use the standard and the maintenance is not in place, this is the cause of the problem of the industrial chiller! The following editor will introduce the causes of corrosion of industrial chillers, what is the relevant content? Reasons for corrosion of industrial chillers: 1. Erosion p...

View details

Cooling method for semiconductor testing chiller to meet temperature control requirements

The biopharmaceutical field requires high-precision temperature to control the activity of enzymes and the production of products; the chemical industry field requires specific temperatures to stabilize chemical reactions; the electronic manufacturing field needs to provide a constant temperature environment for various electronic components to make them stable Work and achieve better performance status, such as: scanning probe microscope, quartz crystal oscillator, electronic linear acceler...

View details

Install a refrigeration unit for the circulating cooling water of the quenching tank

The quenching tank is a container filled with quenching medium. When the workpiece is immersed in the tank for cooling, it must be able to ensure that the workpiece is uniformly quenched at a reasonable cooling rate. It is a container that provides sufficient cooling capacity for the quenching of the workpiece to meet the technical requirements . The quenching tank structure is relatively simple, mainly composed of tank body, medium input or discharge pipe, overflow tank, etc., and some are a...

View details

What aspects should be paid attention to when using laboratory cryogenic refrigeration circulators?

The compact circulating cooler is an economic model for routine laboratory applications. The instrument is cooled in the temperature range of -10 or 0°C to +40°C, and the temperature control accuracy can reach ±0.5°C. It is a good way to replace expensive tap water and is an ideal choice for basic cooling tasks. The lower acquisition cost means they can recover the cost in a short time. The device has its own self-diagnostic function, and there are liquid inlet and outlet ports and switches o...

View details

Troubleshoot the main points of failure of the high and low temperature cooling system

When the industrial high and low temperature cooling system is in use, what is the general reason if the temperature cannot drop down? How should we deal with such failures? Let's first analyze the principles and methods of industrial cooling. The circulating heat transfer medium is different. Generally, the high and low temperature cooling system industry mostly uses direct cooling, while indirect cooling is used, with plate heat exchangers or oil coolers installed inside. In other devices, ...

View details

How to extend the service life of heat transfer oil in dynamic temperature control system?

In the chemical industry, the heat transfer medium of the heat transfer oil of the dynamic temperature control system of the reactor is mainly determined by the heat transfer oil itself, the operating temperature of the heat transfer oil, the dynamic temperature control system equipment, cleaning and heat transfer oil repair and increase the service life. influences. The heat transfer oil of the dynamic temperature control system should be of brand name, not cheap. The quality of heat transfe...

View details LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -