News

Tips on how to save energy for enterprises using industrial chiller

Nowadays, energy conservation has been advocated, and power consumption has always been a concern for everyone. Everyone knows that industrial equipment consumes electricity. For many chemical material manufacturing enterprises, the pressure of the chiller's power consumption is not small, so how to save power is the core of this article! Power-saving tips for industrial chiller: First, avoid and reduce the scale of industrial chiller pipeline If the sewage treatment is not done well, calcium...

View details

Introduction of distillation principle and temperature cycle control device

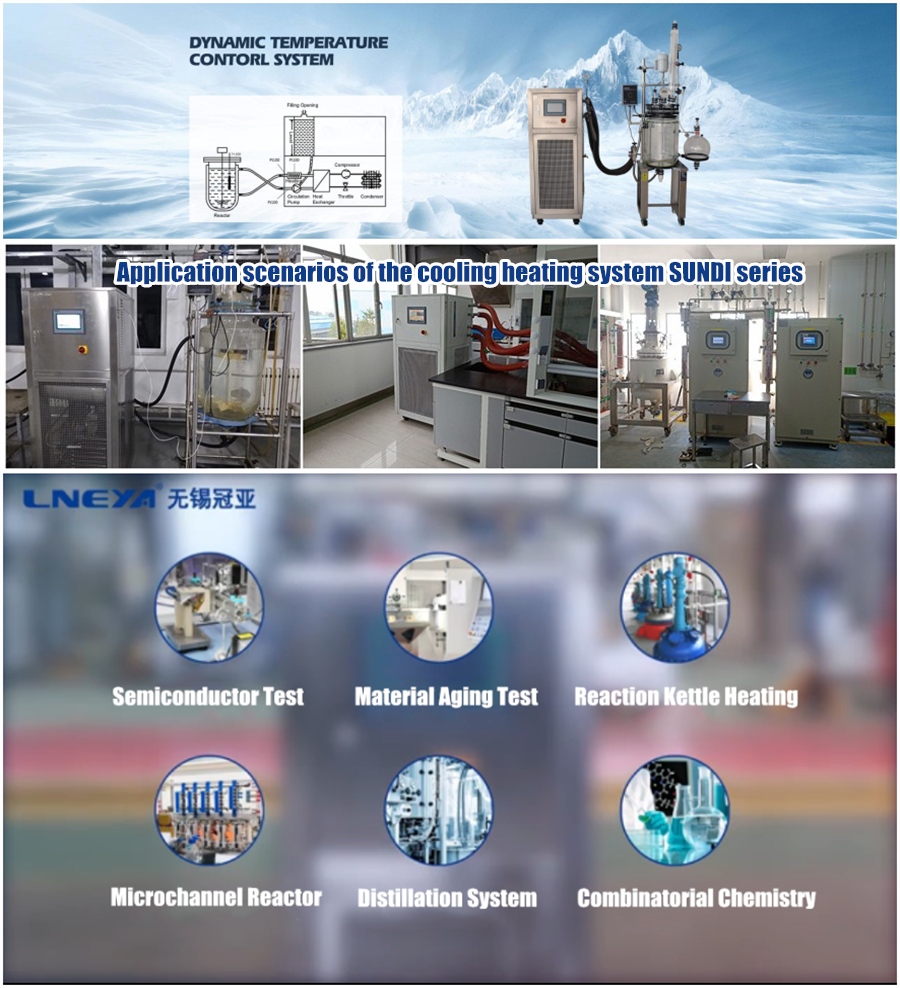

Distillation is a common method for purifying liquid substances and separating mixtures. The boiling point of the compound can also be measured by distillation, so it also has a certain significance for the identification of pure liquid organic compounds. The change of saturated vapor pressure of a substance at different temperatures is the basis of distillation separation. Heating the liquid to boiling makes the liquid into a vapor, and then the vapor is cooled and then condensed into a liqu...

View details

The significance of temperature in IC testing

Every integrated circuit (IC) goes through two type of tests before it can be sold and used to build a product: the first is called a wafer test; the second is called final test. With the improvement of integrated circuit electrical test technology and requirements, some chip products have integrated temperature sensors, or through the voltage changes of some precision diodes linearly related to temperature changes, the current actual chip under test is calculated through a series of formulas...

View details

What do the LNEYA chiller fault codes mean? What is the solution?

Q: What is the fault code of the chiller? Answer: E1 means extremely high indoor temperature alarm, E2 means extremely high temperature alarm, E3 means extremely low temperature alarm, E4 means indoor temperature controller failure, E5 means water temperature sensor failure, E6 means water output alarm, etc. . The fault codes of industrial chillers are in different manufacturers. The fault codes are different. According to the different chiller fault codes, it is easier to find the fault prob...

View detailsAll analysis of refrigerant changing process of industrial chiller unit

Refrigerant is an indispensable part of the refrigeration system of the industrial chiller. During the operation of the industrial refrigeration unit, the refrigerant constantly changes in the industrial refrigeration unit to achieve the cooling effect, so what changes have occurred in the industrial refrigeration unit refrigerant! Let me introduce you to the process of refrigerant changes in industrial refrigeration units. What are the relevant contents? Refrigerant change process of industr...

View details

How to solve the common faults of industrial circulating chillers?

For industrial circulating chillers, if they are always in a high-temperature operating state, a large amount of cold air will be seriously lost. After ensuring the sealing effect of the use environment, effective thermal insulation can be carried out for the industrial chiller in a timely manner to ensure that the industrial circulating chiller is in a stable operating state. Stable operating efficiency can increase the efficiency of lowering the temperature in the unit environment and reduc...

View details

Vapor deposition coating machine temperature control system-cooling water system

The main purpose of the vapor deposition coating machine is to carry out scientific experiments and research on film formation process. It is composed of quartz tube reaction chamber, heat shield furnace cabinet, electrical control system, vacuum system, gas circuit system, temperature control system, pressure control system and gas cylinder cabinet. As part of the PVD process, the temperature of the vacuum chamber must be strictly controlled and the product surface must also be maintained at...

View details

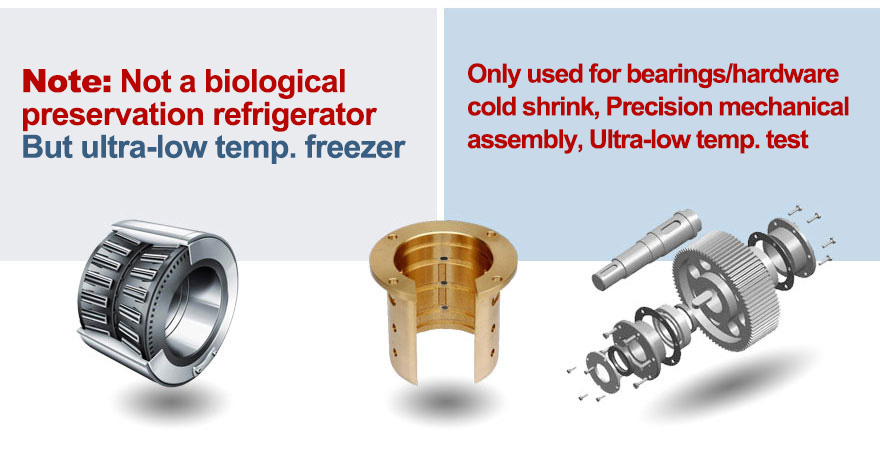

Mechanical cold assembly equipment is dedicated to cold processing assembly of metal parts

Mechanical cold assembly equipment is a method of processing workpieces at temperatures below -130℃. Cryogenic treatment can significantly improve the toughness of the workpiece without reducing the strength and hardness of the workpiece. Mechanical cold assembly equipment is suitable for containing parts (such as planet carrier, torsion arm, etc.). If the parts cannot be heated or heating parts will cause parts accuracy, material organization changes, and affect their mechanical properties, ...

View details

Temperature control during new energy vehicle battery test

With the continuous implementation of energy saving and emission reduction policies, new energy power batteries are also continuously encouraged to develop, and liquid cooling systems have become an inevitable trend for new energy vehicles. The original new energy vehicles can no longer solve the problem of battery heat dissipation by using air-cooled heat dissipation. The advantages of the liquid cooling system of Lneya's KRY high and low temperature coolant tester are fast cooling rate, goo...

View detailsRecommendations for the use of integrated chip test equipment in the test process

From the perspective of the entire semiconductor industry, semiconductors can be divided into R & D, production, and application stages. At different stages, the role of testing is different. Control of test equipment, including test machines, probe stations, sorting machines, etc. Used in different processes and under different working conditions, integrated chip test instruments need to pay attention to some use knowledge when used. Temperature changes on the chip can significantly affe...

View details LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -