Is it right to extend battery life by lowering the ambient temperature?

The battery can work in a wide temperature range, but this does not allow the battery to be charged under high temperature conditions. The charging process is more delicate than the discharging process, and extreme care must be taken. Extreme cold and high temperature will reduce the charge acceptance, so the battery temperature must be adjusted to moderate before charging.

The fast charging limit for most batteries is 5°C to 45°C; for best results, please consider narrowing the temperature range to 10°C to 30°C, because when charging nickel-based batteries below 5°C , The recombination ability of oxygen and hydrogen will decrease. If the charging speed is too fast, pressure will build up in the battery, which may cause exhaust. When charging below freezing point, reduce the charging current of all nickel-based batteries to 0.1°C.

In order to charge quickly at all temperatures, some industrial batteries have added a thermal insulation blanket to heat the battery to an acceptable temperature. Other chargers adjust the charging rate to the current temperature. Therefore, it is recommended that the end user only charge at room temperature.

As the starter batteries in our cars reveal, lead-acid is tolerant under extreme temperatures. Part of the reason for this tolerance is their slow action. The recommended low-temperature charging rate is 0.3°C, which is almost the same as normal conditions. At a comfortable temperature of 20 °C, inflation starts with a charging voltage of 2.415V/cell. When it reaches –20 °C, the deflation threshold rises to 2.97V/cell.

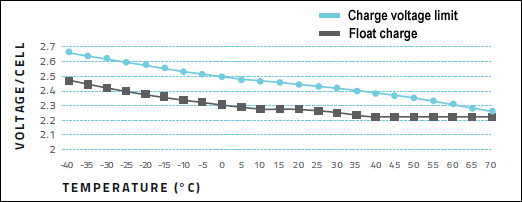

Lead-acid batteries are charged with a constant current to a set voltage, which is usually 2.40V per battery at ambient temperature. This voltage is controlled by temperature and is set higher when cold, and lower when hot. Figure 1 illustrates the recommended settings for most lead-acid batteries.

Freezing a lead-acid battery can cause permanent damage. Always keep the battery fully charged, because in the discharged state, the electrolyte is more like water than when it is fully charged and freezes earlier. A battery full of lead-acid can easily rupture the casing, which can cause leakage if it freezes. The sealed lead-acid bag loses its effectiveness and can only be passed for a few cycles before it fades and needs to be replaced.

Lithium ion can be quickly charged at a temperature of 5°C to 45°C. When it is lower than 5°C, the charging current should be reduced, and due to the decrease of the diffusion rate on the anode, charging is not allowed at the freezing temperature. During the charging process, the internal battery resistance will cause the temperature to rise slightly, thereby making up for some of the cold. When it is cold, the internal resistance of all batteries will increase, which significantly extends the charging time.

Many battery users do not know that consumer-grade lithium-ion batteries cannot be charged below 0°C. Although the battery pack seems to be charged normally, a metallic lithium coating will occur on the anode during the secondary freeze charge. This is permanent and cannot be deleted through a cycle. If exposed to vibration or other stress conditions, lithium-plated batteries are more prone to failure.

Progress is being made in charging lithium ions at temperatures below freezing. Most lithium-ion batteries can indeed be recharged, but only at very low currents. However, some specialty lithium ions can be charged to –10°C at a reduced temperature.

Heat is the worst enemy of batteries, including lead-acid. It is said that adding temperature compensation to the lead-acid charger to adjust for temperature changes can extend battery life by up to 15%. Nickel-based batteries charge at high temperatures will reduce oxygen production, thereby reducing charge acceptance. Heating can fool the charger into thinking that the battery is not fully charged.

Lithium ions perform well at high temperatures, but long-term exposure to heat will reduce their lifespan. Charging and discharging at high temperatures generates gas, which may cause the cylindrical battery to vent gas and cause the pouch battery to swell. Many chargers prohibit charging at temperatures above 50°C.

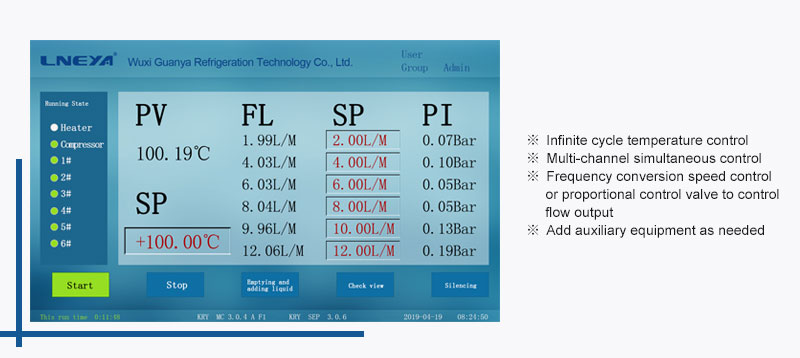

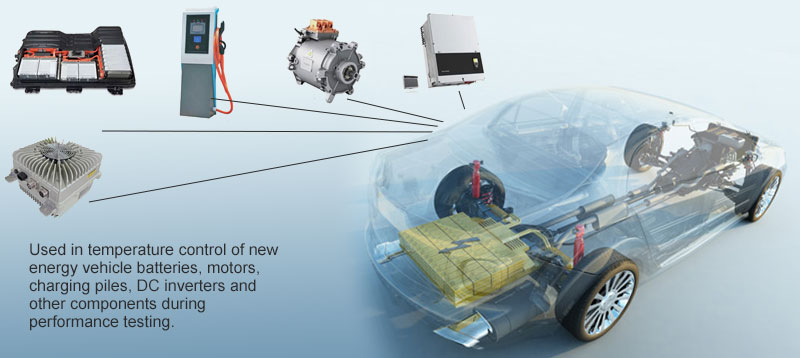

Therefore, for battery manufacturers, battery charging and use testing plays an important role in the production process, because this completely affects their reputation after the product is put on the market. The test environment temperature simulation requires a good temperature control system. The LNEYA battery test cooling device KRY series is specially made for this field. The temperature control range is -40°C to 100°C. The cooling device passes a specific temperature during the battery manufacturer’s test. Curve and record temperature changes, support one KRY to connect to multiple test equipment.

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -