What are the causes of corrosion in industrial chillers / water chillers?

Industrial chillers are now widely used in various industries, but as they become more and more widely used, many problems slowly emerge. Corrosion problems are also relatively common. Because everyone does not use the standard and the maintenance is not in place, this is the cause of the problem of the industrial chiller!

The following editor will introduce the causes of corrosion of industrial chillers, what is the relevant content?

Reasons for corrosion of industrial chillers:

1. Erosion problems caused by unreasonable design ideas and installation plans.

2. When the total number and location of electronic water processor installations are unscientific, the system will cause corrosion.

Industrial chillers have strong electronegative oxygen molecules that can also corrode dirt and rust. but. If the total installation number and location of the electronic water processor are unscientific, it will cause serious erosion to the water system software, and its negative information effect is much higher than the negative effect.

3. Most of the installed decontamination devices are Y-shaped

Installed on the riser, this type of decontamination device can only collect the municipal waste in the early stage of the operation of the machine and equipment, to avoid such waste entering the cooler. However, this type of Y-type filter device v cannot catch fine dirt and rust during normal operation, which will cause the scale of the cooler, sludge and other residues.

4. In the industrial chiller and refrigerated water system software, there is no quick sewage valve in the design of the drain.

At this stage, many enterprises do not have a quick blowdown valve at the end plate of the industrial chiller. The proper way is to solve the problem that the refrigeration system presses the “three open, three close” sewage treatment 2-3 times a week from the outlet side. Every week to solve the problem of refrigerated water system software sewage treatment once this way.

5. There is no smart water meter installed in the FRP cooling tower moisturizing and moisturizing tube and the refrigerated water moisturizing and moisturizing tube.

Since the sewage treatment generally uses drugs to solve, it is necessary to put the drugs according to the water supply flow and the system software water flow. Therefore, these two smart water meters are indispensable in the design concept.

6. Use demineralized water to treat water and moisturize. Surface water will be polluted by potassium ion exchange and waste water will cause environmental pollution.

Special attention in application operation:

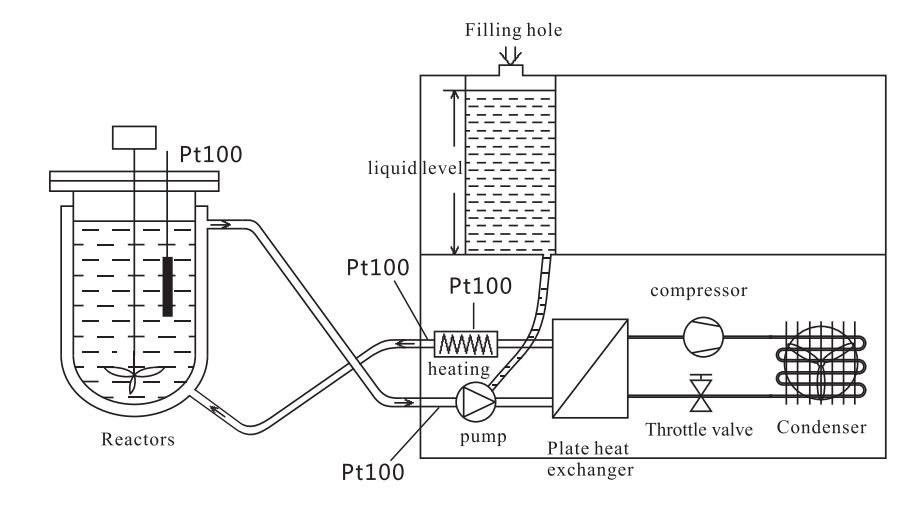

The equipment can be updated and renovated when the temperature is reduced, but it must be carried out in the safety of the machinery and equipment. The water of this commodity must first check that its piping is connected and its gate valve is open during the period of the circulation system. Fully fill the water in the storage tank that requires refrigeration, and then start the centrifugal pump. During the period of operation, the centrifugal pump must pay attention to its operating direction and the reversal of the centrifugal fan. In such cases, we mainly want to ensure that the power supply of the machine and equipment is normal.

The refrigerant liquid in the evaporator is used in all normal applications, and all normal demand is not good enough. The machine has a component called a refrigeration compressor. Check if there is wood to adjust the kinetic energy to a small direction. Remember to open the gate valve on the side. It is inevitable to carry out a closed type on the machinery and equipment or open the gate valve of the machinery and equipment according to the instructions on the machinery and equipment, and check the quality and standards of the automobile fuel tank of the product.

The above is the relevant content of the editor on the cause of corrosion of the industrial chiller. If you still do n’t understand anything, the editor will answer it at any time!

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -