Cooling simulation system for battery pack extreme performance test

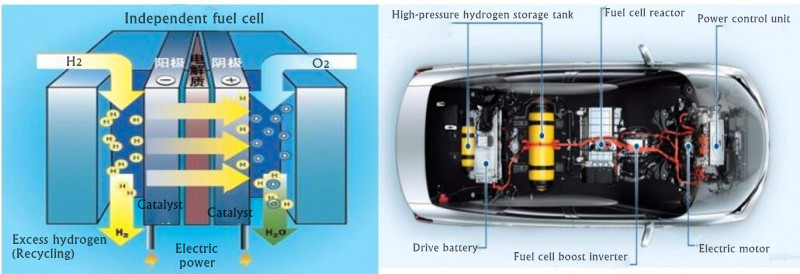

With the development of technology, pure electric vehicles are becoming more and more common, but pure electric vehicles are difficult to get a better solution in terms of cruising range, charging speed, and pollution after battery waste. This makes scientific research workers and related companies in various countries The ideal goal of using energy is to turn to proton exchange membrane fuel cells, thus carrying out a lot of scientific research and real car experiments. In order to improve the service life of the fuel cell and the efficiency, stability and safety of the operation, the modeling and temperature control of the fuel cell system and the power matching between the fuel cell and the vehicle are studied.

According to the laws of mass and heat transfer, conservation of mass and conservation of energy, the researchers established a fuel cell temperature model and a transient temperature model of the fuel cell when the load changes, and analyzed the influence of the air flow on the fuel cell temperature and the system temperature when the work load changed. Variety. The results show that properly increasing the air flow can reduce the temperature of the fuel cell, and the load size is positively correlated with the system temperature, which has certain significance for the temperature control of the fuel cell.

The hydrogen fuel cell test cooling system can provide a stable test platform for fuel cell engines.

It is dedicated to the performance testing of vehicle fuel cell engines. It consists of hydrogen supply system, load system, motor drive system, control system, safety system, etc. The high-pressure hydrogen system supplies hydrogen to the fuel cell engine. The engine outputs electrical energy, which is then converted into rotating mechanical energy by a DC / DC converter and a motor-driven dynamometer.

Fuel cell system, including stack, peripherals and flexible ECU. It contains a one-dimensional PEM-FC stack that allows detailed simulation of water flow, temperature effects and reaction kinetics. It can ensure that the user realistically simulates the fuel cell system, so as to test the ECU in the HiL system. Its modular model architecture allows specific customers to simulate hydrogen, oxygen and cooling systems.

The KRY series of equipment is suitable for a new generation of energy-type battery packs, which can effectively test the battery pack’s super environmental adaptability, improve the safety and reliability of the vehicle, and ensure the vehicle’s good operation in a variety of complex environments. It is widely used in the ultimate performance test of motors and battery packs, rapid thermal shock test, and comprehensive environmental adaptability evaluation test.

Product temperature control range: -40 ~ 120 ℃, temperature control accuracy ± 0.5 ℃; flow / pressure range: 2 ~ 20 L / min, 4 ~ 40 L / min, 4 ~ 60L / min, three flow ranges can be arbitrarily selected, The control accuracy is better than ± 0.2L / min. Frequency conversion flow / pressure control to ensure stable output flow / pressure, intelligent liquid return technology, automatic air blowing to recover the circulating liquid in the test piece. RS485 / CAN / Ethernet multiple communication methods for users to choose, independent modular design, easy to meet user upgrade needs.

(Part of this article comes from an excerpt from the Internet, please contact us if you have any questions!)

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -