Daily maintenance method of heat transfer oil cooling and heating cycle machine

The heat-conducting oil cooling and heating cycle machine is a supporting set of various reactors in the pharmaceutical and chemical industry. The reactor can be used for cooling or heating, and has a high energy efficiency ratio. It does not require a separate computer room and has a small footprint.

The heat transfer oil cooling and heating cycle machine should also pay attention to maintenance at ordinary times, in order to better maintain its operation. Records should be made during daily operation, especially the various phenomena that occur during abnormal operation, such as time and working conditions and other parameters, so as to facilitate the analysis and inspection of the failure of the heat transfer oil cooling and heating cycle machine.

The heat-conducting oil cooling and heating cycle machine should be operated and managed by a dedicated person. If an abnormality is found, it should be shut down and the cause should be identified and troubleshooting. It is strictly forbidden to run the unit with a fault and reach a suitable working state after adjustment. Please do not change the set operating parameters at will. The main circuit power switch cannot be turned off during the normal use period to maintain the normal operation of the compressor oil heater. It is strictly forbidden to operate the switches frequently, the number of starting up should not be 6 times/hour, and the starting time should be more than 5 minutes. The condenser and evaporator should be cleaned at least once every two years.

Whether the fastening bolts of the power supply wiring of the thermal oil cooling and heating cycle machine are loose. Whether the high/low pressure value of the refrigeration/heating system is normal; whether the operating current of the compressor and the resistance of the unit are normal; whether the dryer filter and the sight glass are normal; if the filter outlet is frosted, it indicates that the filter is dirty and needs to be cleaned. Net, if the sight glass shows humidity (the color turns red), you need to replace the dry filter core. Whether the lubricating oil of the compressor is normal. If the oil level is lower than 2/3 of the sight glass during operation, add lubricating oil. If there is dirt or deterioration, replace the lubricating oil, clean or replace the oil filter, and replace at the same time Dry the filter element.

When a fault alarm occurs, first press the red stop button (the alarm light will go out), then check the cause of the fault, and do not force the machine to start operation before the fault is eliminated. If it is not an emergency, it should not be forced to shut down by blocking the main power supply; if it is not used for a long time in winter, shut down the equipment first, then cut off the main power supply, and drain the water in the system.

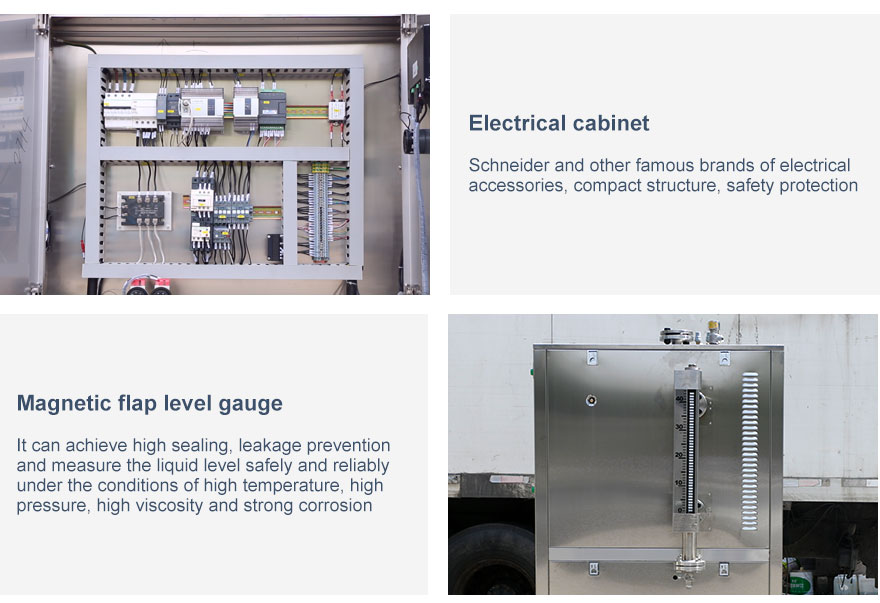

The LNEYA thermal oil cooling and heating cycle machine is an electronic instrument and equipment. It must be cleaned and dusted regularly, and energized regularly to prevent damage to the components. It is necessary to conduct regular part inspection and performance testing to understand its technical status to ensure that the equipment is always in good working condition , Devices that use rechargeable batteries internally to maintain their data or programs should be powered on regularly for use. It is equipped with a multi-function alarm system and safety function. The pump is driven by magnetic force, and there is no problem of shaft seal leakage. The high temperature cooling technology can directly cool down from 300°C to reduce the risk of heat transfer media being oxidized and absorbing moisture in the air.

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -