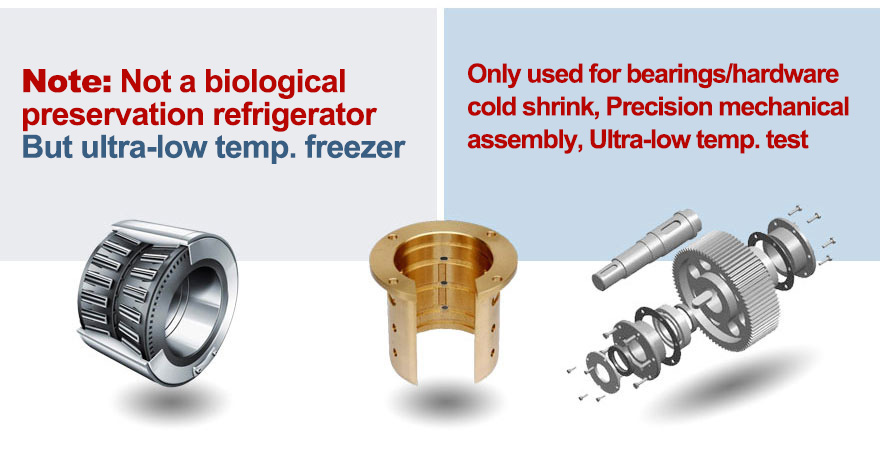

Ultra-low temperature bearing cooling equipment Shrink Fit Bearings and Bushings and Pins

For the metallurgical industry, the oil pressure system of precision machine tools must use refrigeration to control the oil temperature to stabilize the oil film viscosity so that the machine tool can work normally. If applied to steel products, steel can be processed at low temperatures to improve its performance, increase its hardness and strength, and extend its use. life.

Years ago, cutting tools were cryogenically treated by immersing them in liquid nitrogen. This subjected parts to thermal stock and could leave them in a brittle state. Today, cryogenic treatment is a precise, computer-controlled process that ensures stabilization. Parts such as cutting tools are placed in a chamber that is filled with gaseous nitrogen and the temperature is carefully lowered to -300°F.

Nowadays, LNEYA’s bearing cold shrink processing box is used for industrial cold treatment, using automatic cascade supercooling refrigeration technology, frozen bearing, metal and other precision instrument parts, industrial cold shrink gear box gear, engine parts clearance fit, interference fit, etc. , Non-standard sizes can be customized as needed.

What does freezing a bearing do?

Freezing bearings causes the metal to contract slightly and therefore makes it easier to fit the bearing into its housing. When used in conjunction with heating of the housing metal, freezing a bearing is highly effective as an installation method.

Cryogenic treatment can be used with coated or uncoated tool steels. It produces microstructural changes in the grain of the metal, eliminating voids and imperfections caused by the heat treatment process. Although conventional heat treatment imparts hardness and toughness to tool steels, the metal still contains soft iron (austenite) and a non-uniform structure. Cryogenic treatment converts the remaining austenite into hard iron (martensite), which improves mechanical properties such as hardness and toughness along with tribological properties such as wear resistance and coefficient of friction.

The Benefits of Cryo-Treatment

Tool steel specimens that were cryo-treated had 80% better wear resistance than specimens that were untreated. Because cryogenic treatment also relieves stresses and improves durability, manufacturers and machine shops can expect longer cutting tool life.

Cutting tools that are cryogenically treated also improve productivity, promote quality, and support applications that require higher cutting speeds and feed rates. Broaches, drills, milling cutters, reamers, taps and other cutting tools that remain within specification produce better-quality parts that require less regrinding, reshaping, or rework. Cryo-treated cutting tools also have improved thermal conductivity, enabling them to better handle the higher heat associated with faster cutting operations for greater throughputs.

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -