CDLJ -110℃~-50℃

Can be use for cannabis extraction- Cooling capacity @-105℃2kW~120kW

- Power range14kW~768kW

- Expansion tank50L~400L

- RefrigerantR404A/R23/R14

- Weight950KG~9000KG

- Place of OriginChina

Product data download

5kW Chiller; 10kW Chiller; 30kW Chiller; 60kW Chiller; 120kW Chiller

Widely used in chemical, pharmaceutical, biochemical and other industries in the field of low temperature reaction, refrigeration speed, safety and reliability.

Single fluid low-temperature refrigeration units in the pharmaceutical and chemical industry

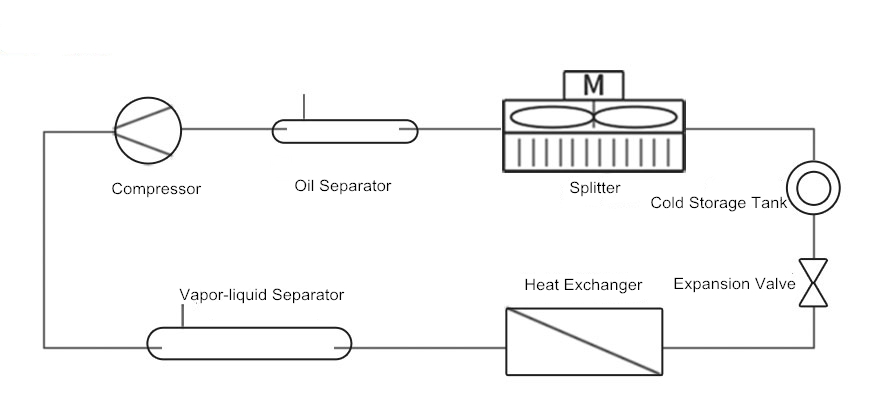

Adopting single machine cascade refrigeration and secondary subcooling technology

Fast cooling, low cooling temperature

Control Temperature

-5~-150 ° C

Cooling method

Water-cooled/cooling

Configuration Details

| Model | CDLJ-2W | CDLJ-3W | CDLJ-6W | CDLJ-10W | CDLJ-15W | CDLJ-20W | CDLJ-45W | CDLJ-60W | CDLJ-90W |

| Temperature Range | -110°C~ -50°C | ||||||||

| Cooling Capacity At -110°C |

2kW | 3kW | 6kW | 10kW | 15kW | 20kW | 45kW | 60kW | 120kW |

| 1720Kcal/h | 2580Kcal/h | 5160Kcal/h | 8600Kcal/h | 25800Kcal/h | 17200Kcal/h | 38700Kcal/h | 51600Kcal/h | 103200Kcal/h | |

| Circulation Pump Info | 6.6m³/h | 6.6m³/h | 15m³/h | 15m³/h | 15m³/h | 25m³/h | / | / | / |

| 2.5bar max | 2.5bar max | 2.5bar max | 2.5bar max | 2.5bar max | 2.5bar max | / | / | / | |

| Inlet&outlet connection size | DN-25 PN-10 |

DN-25 PN-10 |

DN-40 PN-10 |

DN-40 PN-10 |

DN-40 PN-10 |

DN-50 PN-10 |

DN-65 PN-10 |

DN-65 PN-10 |

DN-80 PN-10 |

| Cooling Water at 30 degree | 10m³/h | 14m³/h | 25m³/h | 35m³/h | 45m³/h | 65m³/h | 120m³/h | 180m³/h | 360m³/h |

| Expansion tank(standard) | 50L | 75L | 150L | 200L | 300L | 300L | / | / | / |

| Compressor | Dorin semi-closed compressor | Dorin compressor/HANBELL、Fusheng、Bitzer screw compressor | |||||||

| Operation Panel | 7-inch color touch screen display, temperature curve record | ||||||||

| Control System | PLC&Module,Set temperature difference of refrigeration on & off | ||||||||

| Circulation Pump | The whole system is a full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supplement oil automatically at low temperature | ||||||||

| Circulation Pump | LNEYA Mangetic Pump | ||||||||

| Evaporator | Plate heat exchanger | ||||||||

| Condenser | Casing type water-cooled condenser / tube-type water-cooled condenser | ||||||||

| Intermediate heat exchanger | Plate heat exchanger | ||||||||

| Electric | AC contactors, intermediate relays, circuit breakers, thermal relays, etc. are Schneider / ABB brand | ||||||||

| Refrigerant | R404A/R23/R14 | ||||||||

| Secondary refrigerant | Ethanol, dichloromethane, heat transfer oil, etc. | ||||||||

| Safety Protection | High pressure protect; water supply cut-off protection; over-current protection; leakage protection; sequential and phase failure protection; High temperature protection; Sensor Failure protection; Liquid low level protection etc. multi-safety protection | ||||||||

| Level Indicator | Adopt glass liquid level indication | ||||||||

| Piping material | Expansion tank, cold storage tank and circulation pipeline are all made of SUS304 | ||||||||

| Case material | Channel steel + square tube + cold rolled plate sealing plate spray 7035 | ||||||||

| Dimension cm | 100*150*185 | 200*145*205 | 250*145*225 | 250*145*225 | 300*160*225 | 350*160*245 | 500*200*260 | 650*200*260 | 1000*240*260 |

| Power | 16kW | 25kW | 50kW | 69kW | 101kW | 136kW | 295kW | 396kW | 768kW |

| dB | within 75 dB | within 90 dB | |||||||

| Weight (kg) | 950kg | 1100kg | 1800kg | 2200kg | 3000kg | 3500kg | 5000kg | 6000kg | 9000kg |

| Optional | Optional outside touch screen display controller (separated), the communication line distance is 10 meter | ||||||||

| Optional | Optional explosion-proof touch screen control system (ExdeIIBT4), the communication line distance is 15 meter | ||||||||

Product Description

1.Temperature ranges from -5℃ ~ -150℃, can meet different temperature

2. Famous brand semi-closed piston compressor, semi-closed bipolar piston compressor, semi-hermetic screw compressor, main brand are BOCK. Bitzer, Copeland, Handbell, fusheng; Plate heat exchanger, Small volume, High efficiency

3. Top imported cold controller; Generator cooling water circuit uses intermediate heat exchanger, improve system reliability and safety.

4. DANFOSS electronic expansion valve, high precision control;

5. Adopt Siemens PLC S7-200/300, LNEYA touch screen, automatic control, temperature curve display, temperature record U disk, fault alarm;

6. Offer machine installation and system test, users only need to finish the installation of refrigerant and cooling water.

Used for rapid liquid refrigeration/cooling

Widely used in high-tech industries such as petrochemicals, healthcare, pharmaceuticals, biochemistry, freeze-drying, and military industry.

Chiller Knowledge

How Long Does the Cold Water Machine in the Lab Need to be Cleaned?

After running for a period of time, Lab Chiller CDLJ -115℃~-50℃ requires for the protection and the maintenance of all. If the laboratory chillers lack the necessary maintenance and protection, it means the high operation defect rate of the laboratory chiller.

When running laboratory cold water machine, it needs a thorough clean for the machine to keep the laboratory machine safe and stable after using half a year’s time.

If cooling water machine for laboratory use frequency is higher, and the environment is relatively bad, to avoid the probability of all kinds of problems of industrial laboratory cold water machine, you should be able to shorten the clean time to once every three months.

The specific time about cleaning the laboratory water chiller is determined by using environment of the company. If the environment is relatively clean, the company can put off cleaning time, whereas company needs to clean it ahead of schedule in order to keep the laboratory chiller operation safe, prevent all kinds of problems in case to affect the company normal use of laboratory chiller.

REQUEST A QUOTE

recommend products

LTZ -115°C~ 90°C

For Pharmaceutical & chemical industrysingle fluid low temperature refrigeration unittemperature controlcooling methodTemperature Control Range-115℃~-80℃Product DescriptionApplicationsrecommend products *Are-cooled and Water-cooled Type…

LN -60°C~ -10°C

Product data downloadPharmaceutical & chemical industrysingle fluid low temperature refrigeration unittemperature controlcooling methodConfiguration DetailsProduct DescriptionWhat is Single machine auto cascade?Local equipmentColor touch scree…

LT -80℃~-20℃

Industrial Air Chiller UnitLOW TEMP. REFRIGERATION CIRCULATORProductDescriptionCooling MethodData Communication InterfaceAPPLICATION SCENARIOProduct ApplicationsRecommend products It can guarantee 24-hour continuous operation …

Hot & Cold Dual Circuit Temp Control Units

Remote control100%helium detection100%safety regulationsFrequency regulationHot and cold dual-channelHot test 80°C~125°℃ For 120°C high temperature heating and dryingCold test -15°c~30°℃ The other side is used for cooling and capturing at 25°CDUAL…

LTZ Variable frequency M series

Industry temperature control solutionsLTZ variable frequency chillerDETAIL ADVANTAGE,STRIVING FOR EXCELLENCEParameterWIND COLD WATER COLD ON DEMAND SELECTIONCASCADECOMMUNICATION REMOTE OPERATIONrecommend products It is suitable for the target…

LTG Screw chiller units

LTG series Screw ChillersPLC control7-inch screen100% safety regulations100% helium detectionFrequency controlAll LTG series screw chiller modelsWORKING PRINCIPLE OF REFRIGERATION AND COOLINGDETAIL ADVANTAGE,STRIVING FOR EXCELLENCEWIDE RANGE OFAPP…

ZLTZ -10°C~ 25°C

Suitable for temperature control applications such as microchannelreactors, plate heat exchangers, cold plates, heat sink plates, andtubular reactors with small heat exchange areas, large refrigerationcapacities, and small temperature differences;…

LT-800

For laboratory rotary evaporatorMINI CHILLER/SMALL WATER CHILLERMicrocomputer control, accurate temperature controlREQUEST A QUOTErecommend products The image only shows the connection effect …

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -