Search the whole station

(Normal Temp Series)

WhatsApp: 086 13912479193

WeChat 86 15152266993

temperature accuracy is ± 0.1 ℃

Stable performance

capable of working continuously for 24 hours

Cooling Power High to 50kW

| Model | LT-1 | LT-2 | LT-3 | LT-4 | LT-6 | LT-8 | LT-13 | LT-20 | |

| Medium temperature range | Standard LT series temperature range 10℃~35℃ Only cooling function (medium ethylene glycol aqueous solution -0℃) | ||||||||

| Temperature control | ASET multi-function controller, controls water tank temperature | PLC controller, controls the water tank outlet temperature | |||||||

| Temperature feedback | Temperature feedback PT100 | ||||||||

| Temperature control accuracy | ±0.5℃ | ||||||||

| Cooling capacity | 20℃ | 3kW | 5kW | 7.5kW | 10kW | 14kW | 20kW | 30kW | 50kW |

| Circulation pump maximum flow | 35L/min | 35L/min | 35L/min | 110L/min | 110L/min | 110L/min | 200L/min | 250L/min | |

| Circulation pump maximum pressure | 1.6BAR | 1.6BAR | 1.6BAR | 1.8BAR | 1.8BAR | 1.8BAR | 2.5BAR | 2.5BAR | |

| Compressor | Songyang/Mitsubishi/Hitachi/Copeland compressor | ||||||||

| Evaporator | Plate Heat Exchanger | ||||||||

| Operation panel | Display the set temperature and measured temperature, touch key operation to input temperature | 7-inch color touch screen displays set temperature and measured temperature | |||||||

| Security | It has multiple safety functions such as self-diagnosis function, refrigerator overload protection, high pressure switch, overload relay, thermal protection device, etc. | ||||||||

| Refrigerant | R134A/R404A/R407C | ||||||||

| Connection size | ZG1/2 | ZG3/4 | ZG3/4 | ZG3/4 | ZG1 | ZG1 1/4 | DN40 PN10 | DN40 PN10 | |

| Dimensions(cm) | 38*57*60 | 40*90*103 | 40*90*103 | 50*110*120 | 50*110*120 | 50*110*120 | 100*150*205 | 145*245*225 | |

| Weight | 115kg | 145kg | 180kg | 225kg | 290kg | 340kg | 560kg | 800kg | |

| Power(max) 50HZ |

AC220V 1.5kW |

AC220V 2.2kW |

AC220V 4kW |

AC380V 6kW |

AC380V 9kW |

AC380V 12kW |

AC380V 18kW |

AC380V 34kW |

|

| Shell material | Cold rolled sheet spraying | ||||||||

| Optional | Optional 7-inch color touch screen, record temperature curve, data export in Excel format | ||||||||

| Optional | SUS304 shell | ||||||||

| Optional | Silicon rubber tube/304 steel tube | ||||||||

| Optional power supply | 220V 60HZ Three-phase,440V~480V 60HZ Three-phase | ||||||||

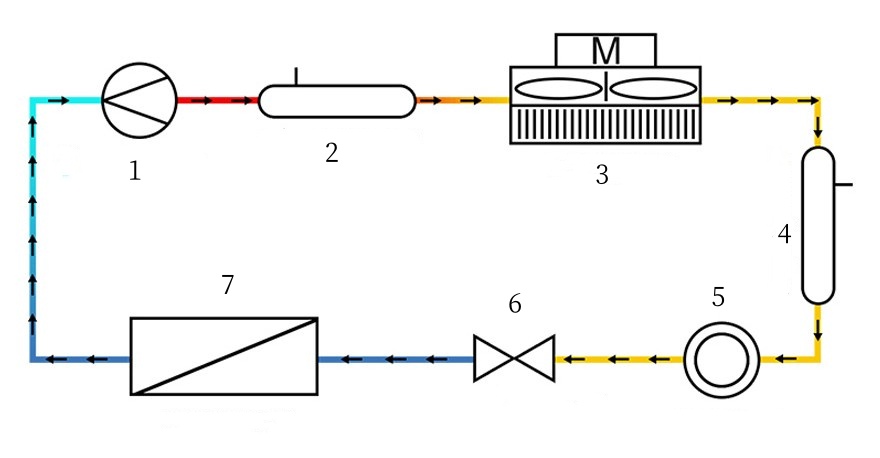

The entire working principle process can be roughly divided into three parts: water circulation system, refrigeration circulation system, and main control system. The water circulation system is also a part that directly reflects the function of industrial chillers. It transfers cold water to the equipment that needs to be cooled, absorbs the heat from the equipment, and then transfers it back. A refrigeration cycle system is the process of cooling cold water that absorbs heat. The refrigerant sublimates and then compresses, carrying the heat from the cold water outdoors for heat dissipation. The main control system is part of power control and internal structural component control.

Cooling of the hot part of the semiconductor manufacturing device:

Single wafer cleaning transfer, printing machine, automatic holder mounting device, spraying device, ion plating device, etching device, single wafer processing device, slicer, packaging machine, temperature management of developer, exposure device, heating of magnetic part Device, etc.

Cooling of the heating part of the laser device:

Laser processing, heat generation part of fusion splicer, laser marking device, generating device, carbon dioxide laser processing machine, etc.

Cooling of the heating part of other industrial machines:

Plasma welding, automatic packaging machine, mold cooling, washing machine, gold plating tank, precision grinding machine, injection molding machine, molding part of resin molding machine, etc.

Analyze the cooling of the hot part of the machine:

The light source of the electron microscope, the light source portion of the ICP emission spectroscopic analyzer, the heat generating portion of the spectrophotometer, the heat source of the X-ray analyzing device, the heat generating portion of the automatic pulse banner device, and the light source of the atomic absorption photometer.

Cooling of the cooling medium of CNC machine tools and machining centers.

for vacuum pump

for Special gas factory

for Semiconductor production

for chemical reaction

for Material manufacturing

for Steel pipe cold drawing machine

for Material testing

for low temperature reaction

Outdoor Chiller

Indoor Chiller

Air and Water Type

Temperature Control :-5℃~-150℃

Cooling Power: 1.5kW~780kW

WhatsApp: 086 13912479193

WeChat 86 15152266993