KRY 0℃~100℃ 1&6S

Normal temperature chiller for vehicle antifreeze test temperature simulation- Heating Power15kW~38kW

- Cooling capacity18kW~60kW

- Power range38kW~82kW

- Temperature accuracy±0.5℃

- Flow rate output2~50 L/min

- RefrigerantR404A/R507C/R125/N40

- Weight900KG~1950KG

Product data download

KRY 0℃~100℃ 1&6S (6 sets of auxiliary temperature control, pressure and flow controlled separately)

| Model | KRY-A25W/6S | KRY-A38W/6S | KRY-A60W/6S | |

| Temp. Range | 0℃~+100℃ | |||

| Temp. control precision | ±0.5℃ | ±0.5℃ | ±0.5℃ | |

| Temp. feedback | Pt100 | Pt100 | Pt100 | |

| Temp. display | 0.01k | 0.01k | 0.01k | |

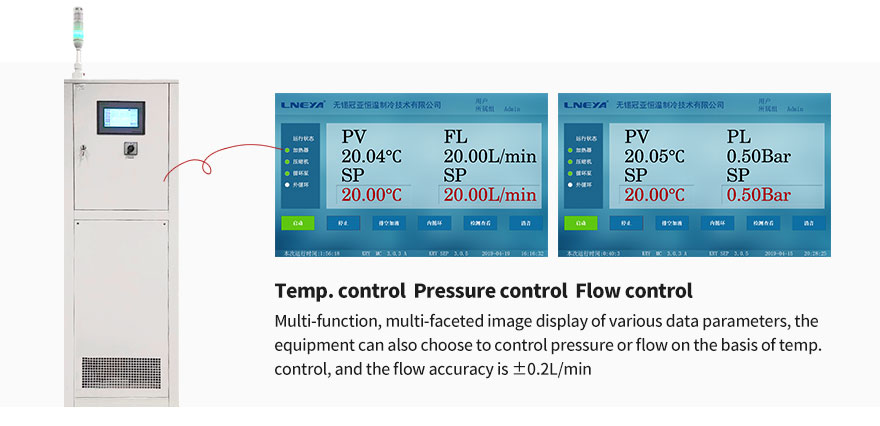

| Flow control/Group | 2~20 L/min | 2~20 L/min | 2~20 L/min | |

| Flow control accuracy/Group | ±0.2L | ±0.2L | ±0.2L | |

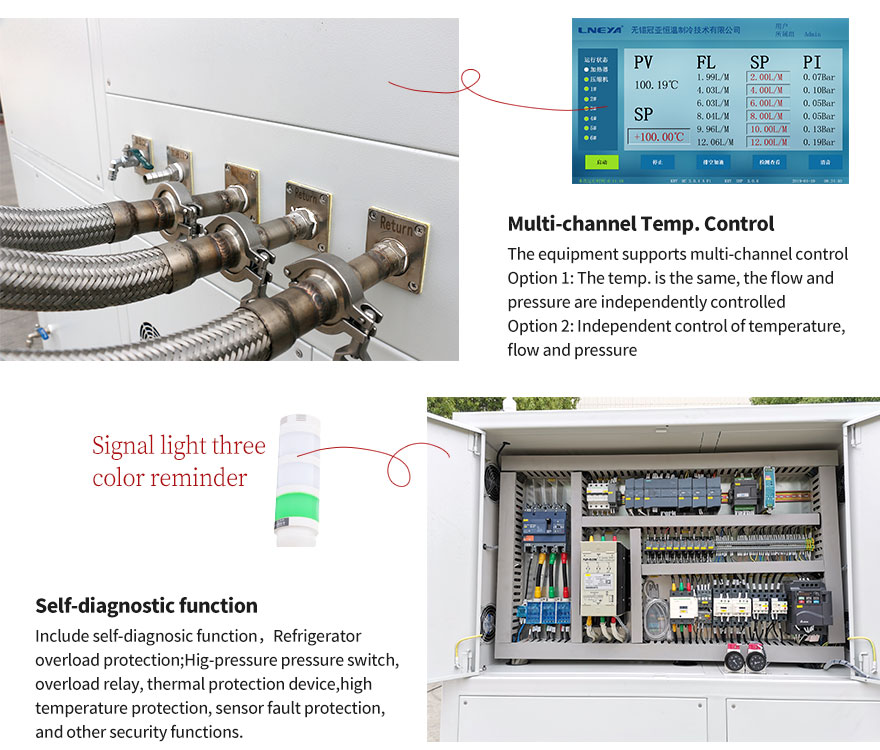

| Number of fluid output groups | 6 Groups | 6 Groups | 6 Groups | |

| pressure control/Group | 0.2bar~2.5bar | 0.2bar~2.5bar | 0.2bar~2.5bar | |

| flow pressure description | The equipment can control flow and pressure separately. need to control at the same time using different solutions (to be customized) | |||

| Heating power | 15kW | 25kW | 38kW | |

| cooling capacity | 100℃ | 25kW | 38kW | 60kW |

| 20℃ | 25kW | 38kW | 60kW | |

| 5℃ | 18kW | 27kW | 42kW | |

| compression | Emerson Valley Wheel Compressor | |||

| expansion | Electronic Expansion Valve | |||

| oil distributor | Emerson | |||

| Dry filter, Pressure | Danfoss | |||

| Evaporator | Plate heat exchanger | |||

| Ciriulating pump | Nangfang centrifugal pump can be selected with imported brand magnetic pump | |||

| Frequency | Delta | |||

| Flow, Pressure sensor | German brand flowmeter, johnson Controls pressure | |||

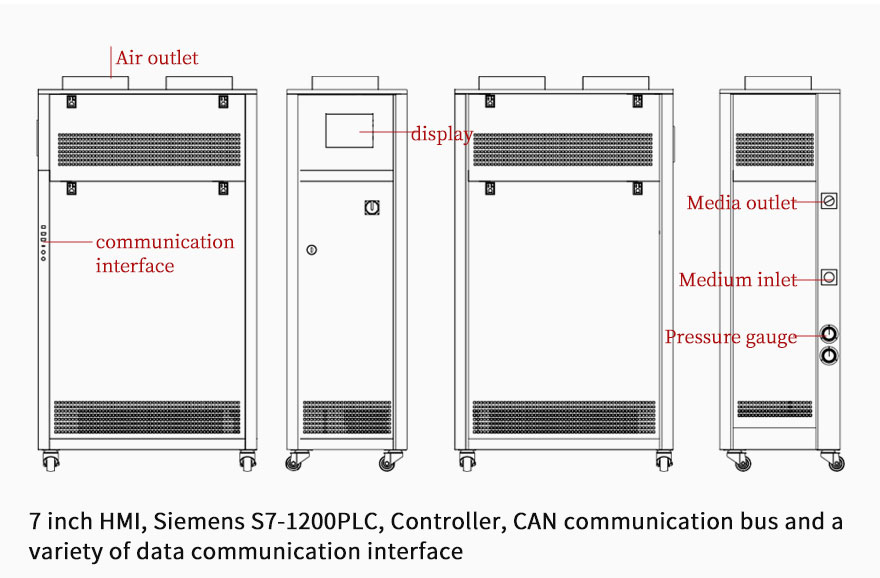

| input, Display | 5 inch color touch screen \ PLC controller | |||

| Communication | Modbus RTU protocol RS485 interface, optional CAN communication bus, Ethernet interface TCP/IP protocol | |||

| Safety protection | With self-diagnosis function; Refrigerator overload protection; High pressure switch, overload relay, thermal protection | |||

| device, low liquid level protection, high temperature protection, sensor fault protection and other safety functions | ||||

| is it a fully closed system | The whole system is a fully closed system, there will be no oil mist at high temperature, and the water in the air will not be absorbed at low temperature. The system will not increase the pressure due to high temperature in operation, and the thermal conduction medium will be automatically supplemented at low temperature. | |||

| refrigerant | R404A/R507C/R125/N40 All four refrigerants are available | |||

| Connection size | There are six groups of inlet and outlet,ZG3/4 | |||

| Cooling water at 20C° | 6000L/H | 9000L/H | 15000L/H | |

| Condenser(W) | Shenshi tube type heat exchanger | |||

| Power 380V50HZ | 38kW | 55kW | 82kW | |

| Dimension cm | 200*145*205 | 200*145*205 | 200*145*205 | |

| Weight | 900kg | 1200kg | 1950kg | |

| Optional | 220V 60HZ three phase 460V 60H three phase | |||

| Optional | Extend to -40~+135℃ | |||

| Optional | The size external circulation pipe line is DN15 or DN20, do not throttle, which will increase the circulation pump load, | |||

| pipe need to be insulated, and adopt rubber and plastic insulation pipe which can afford high temp. | ||||

| Optional | When the temperature is lower than the normal temperature, the refrigeration system adopts the refrigeration PID to adjust the cooling capacity, and does not adopt the heating countermeasures, so as to achieve the purpose of energy saving | |||

Product Description

Working Principle

Temperature simulation for vehicle quality test: battery life test, fuel injector/motor test bench, airbag test, component test bench, etc. It can simulate the external environmental conditions in the climate chamber or replace the internal system, which can create the necessary actual temperature conditions for the test bench.

Test temperature of main test items of vehicle electronics:

IC test conditions for locomotives: -40℃~125℃, wind blowing, sun exposure, high vibration;

Instrument panel operation test test conditions: -40℃~85℃;

Motor controller test conditions: operating test temperature: 40 ℃ ~ 110 ℃;

Satellite positioning (GPS) Test conditions: high temperature operation test temperature: 85℃; low temperature operation test temperature: -40℃;

Compound vibration: -40℃~80℃;

Obviously the best solution is for the test house to have temperature simulation system equipment.

You may also be interested in these products

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -