KRY 0℃~100℃ 1&2S

Normal temperature chiller for vehicle antifreeze test- Heating Power10kW~38kW

- Cooling capacity7kW~60kW

- Power range17kW~65kW

- Temperature accuracy±0.5℃

- Flow rate output2~50 L/min

- RefrigerantR404A/R507C/R125/N40

- Weight360KG~1700KG

Product data download

- manual.pdf

Parameters Description

| Model | KRY-75/2S | KRY-A15/2S | KRY-A25W/2S | KRY-A38W/2S | KRY-A60W/2S | |

| KRY-75W/2S | KRY-A15W/2S | |||||

| Temp. Range | 0℃~+100℃ | |||||

| Temp. control precision | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | |

| Temp. feedback | Pt100 | Pt100 | Pt100 | Pt100 | Pt100 | |

| Temp. display | 0.01k | 0.01k | 0.01k | 0.01k | 0.01k | |

| Flow control/Group | 2~25 L/min | 2~25 L/min | 2~25L/min | 5~50 L/min | 5~50 L/min | |

| Flow control accuracy/Group | ±0.2L | ±0.2L | ±0.2L | ±0.2L | ±0.2L | |

| Number of fluid output groups | 2 Groups | 2 Groups | 2 Groups | 2 Groups | 2 Groups | |

| pressure control/Group | 0.2bar~2.5bar | 0.2bar~2.5bar | 0.2bar~2.5bar | 0.2bar~2.5bar | 0.2bar~2.5bar | |

| flow pressure description | The equipment can control flow and pressure separately. need to control at the same time using different solutions (to be customized) | |||||

| Heating power | 10kW | 10kW | 15kW | 25kW | 38kW | |

| cooling capacity | 100℃ | 10kW | 15kW | 25kW | 38kW | 60kW |

| 20℃ | 10kW | 15kW | 25kW | 38kW | 60kW | |

| 5℃ | 7kW | 11kW | 18kW | 27kW | 42kW | |

| compression | Emerson Valley Wheel Compressor | |||||

| expansion | Danfoss Thermal Expansion Valve/ Emerson Solenoid | |||||

| oil distributor | Emerson | |||||

| Dry filter, Pressure | Emerson/Danfoss | |||||

| Evaporator | Plate heat exchanger | |||||

| Ciriulating pump | Magnetic pump | |||||

| Frequency | Delta | |||||

| Flow, Pressure sensor | German brand flowmeter, johnson Controls pressure | |||||

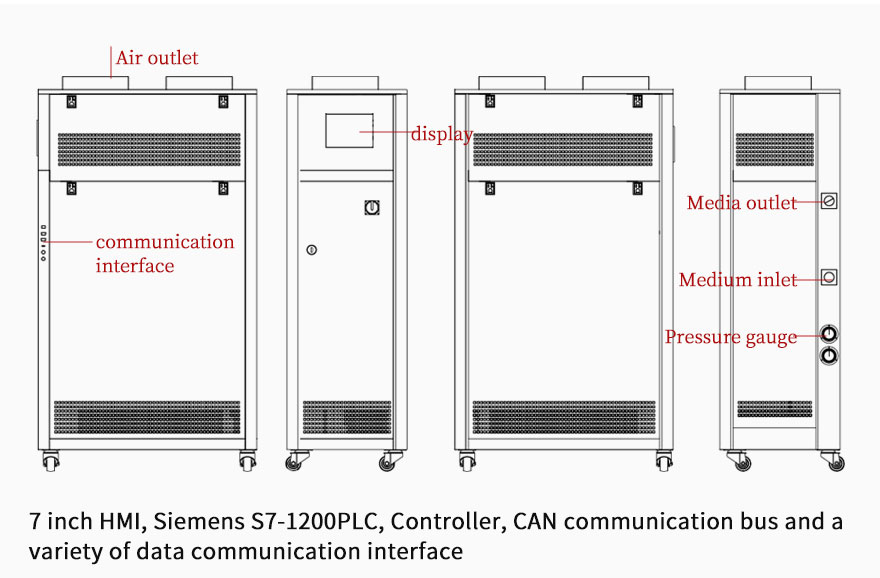

| input, Display | 5 inch color touch screen \ Siemens S7-1200 PLC controller | |||||

| Communication | Modbus RTU protocol RS485 interface, optional CAN communication bus, Ethernet interface TCP/IP protocol | |||||

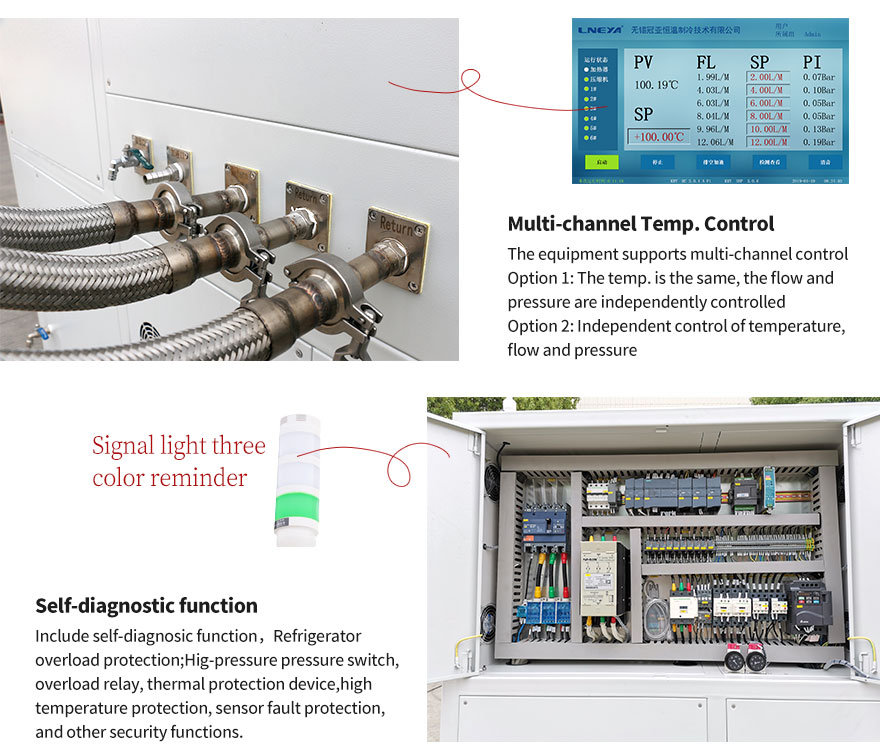

| Safety protection | With self-diagnosis function; Refrigerator overload protection; High pressure switch, overload relay, thermal protection | |||||

| device, low liquid level protection, high temperature protection, sensor fault protection and other safety functions | ||||||

| refrigerant | R404A/R507C/R125/N40 All four refrigerants are available | |||||

| Connection size | There are two groups of inlet and outlet,G3/4 | |||||

| Cooling water at 20C° | 2600L/H | 3200L/H | 6000L/H | 9000L/H | 15000L/H | |

| Condenser(W) | Shenshi tube type heat exchanger | |||||

| Power 380V50HZ | 17kW | 20kW | 31kW | 43kW | 65kW | |

| Dimension cm | 70*100*175 | 80*120*185 | 100*150*185 | 120*180*205 | 145*205*225 | |

| Weight | 360KG | 450kg | 750kg | 1000kg | 1700kg | |

| Optional | 220V 60HZ three phase 460V 60H three phase | |||||

Product Description

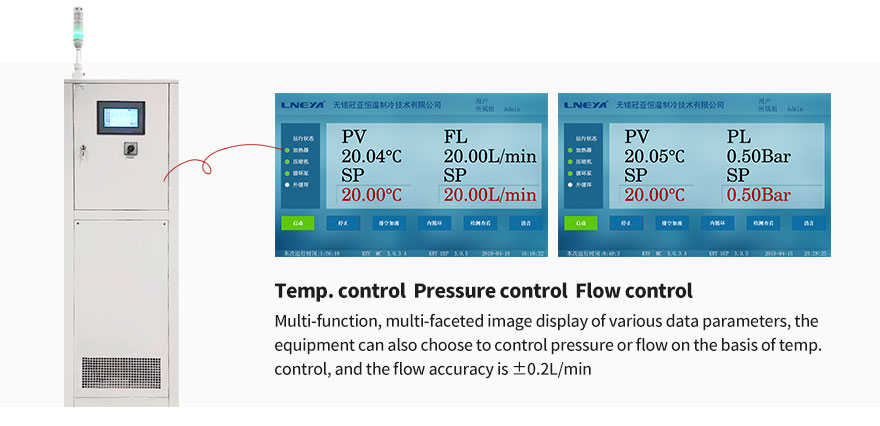

Temperature range is 0℃~+100℃, which can be extended to +135℃ according to the actual situation, and the temperature control accuracy is plus or minus 0.5℃. The equipment can control the flow and pressure independently while controlling the temperature, and different customized solutions are required for simultaneous control.

Equipped with a powerful circulation pump while ensuring the delivery of highly viscous liquids.

Control the flow output with variable frequency regulation or proportional control valve to achieve high precision control total range 5%~100% adjustment.

Test temperature of main test items of vehicle electronics:

IC test conditions for locomotives: -40℃~125℃, wind blowing, sun exposure, high vibration;

Instrument panel operation test test conditions: -40℃~85℃;

Motor controller test conditions: operating test temperature: 40 ℃ ~ 110 ℃;

Satellite positioning (GPS) Test conditions: high temperature operation test temperature: 85℃; low temperature operation test temperature: -40℃;

Compound vibration: -40℃~80℃;

Obviously the best solution is for the test house to have temperature simulation system equipment.

You may also be interested in these products

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -