Semiconductor Cooling Chiller

FLTZ -45℃~90℃- Temperture accuracy±0.1℃

- Flow control25~75/min 6bar max

- RefrigentR404A

- Power range380V 3.5kW~16kW

Product data download

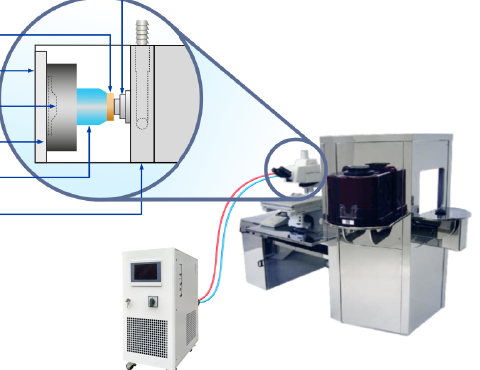

Temperature control in semiconductor production and testing processes

Heating method within 40 ℃ adopts a compressor hot gas heating fully enclosed design, and the machine operates continuously for 24 hours

Ensure stable and reliable overall semiconductor process flow from front-end to back-end

Product Description

The semiconductor temperature control device Chiller is mainly used for precise temperature control in semiconductor production and testing processes. Its products include fluid fluorinated liquid temperature control (minimum -100 degrees), rapid temperature change of gas cooling and heating, rapid temperature change chuck, low-temperature gas refrigeration machine (-120 degrees), direct cooling refrigeration unit (-150 degrees), etc. The company applies various algorithms (PID, feedforward PID, and model free self built tree algorithm) in the system to achieve fast response and high control accuracy.

The important information such as the exhaust and suction temperature (pressure), condensation temperature, cooling water temperature (pressure), inlet and outlet liquid (gas) temperature (pressure), electrical power, current and voltage of each component, and water tank level of the chiller are all comprehensively managed, monitored and recorded through sensors connected to the control system.

Heating method within 40 ℃ adopts compressor hot gas heating.

The chiller circulation system adopts a fully enclosed design, and the circulation pump adopts a magnetic drive pump.

Chiller 100% helium testing, 100% safety regulations testing to ensure system safety and reliability.

The chiller runs the copying machine continuously for 24 hours at 100%.

chillers that control the processing temperature on the Fab equipments

Single channel air-cooled cooler, mainly designed for etching machines. It is used to provide independent temperature control for the chamber side walls.

Configuration Details

|

Model |

FLTZ-002 FLTZ-002W |

FLTZ-003 FLTZ-003W |

FLTZ-004 FLTZ-004W |

FLTZ-006 FLTZ-006W |

FLTZ-008 FLTZ-008W |

FLTZ-010 FLTZ-010W |

FLTZ-015 FLTZ-015W |

|

Tempearature Control |

5℃~90℃ |

||||||

|

Temperature accuracy |

±0.05℃ |

||||||

|

Flow control |

10~25L/min 5bar max |

15~45L/min 6bar max |

25~75L/min 6bar max |

||||

|

Refrigeration capacity@10℃ |

6kw |

8kw |

10kw |

15 kw |

20kw |

25kw |

40kw |

|

Internal circulation liquid volume |

4L |

5L |

6L |

8L |

10L |

12L |

20L |

|

Expansion tank capacity |

10L |

10L |

15L |

15L |

20L |

25L |

35L |

|

Refrigerant |

R410A |

||||||

|

Secondary Refrigerant |

Silicone oil, fluorinated liquid, ethylene glycol aqueous solution, DI, etc. (DI temperature needs to be controlled above 10 ℃) |

||||||

|

Entry and exit interfaces |

ZG1/2 |

ZG1/2 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG1 |

ZG1 |

|

Cooling water outlet |

ZG1/2 |

ZG1/2 |

ZG3/4 |

ZG1 |

ZG1 |

ZG1 |

ZG1 1/8 |

|

Cooling water flow rate@20℃ |

1.5m³/h |

2m³/h |

2.5m³/h |

4m³/h |

4.5m³/h |

5.6m³/h |

9m³/h |

|

power supply 380V |

3.5kW |

4kW |

5.5kW |

7kW |

9.5kW |

12kW |

16kW |

|

Temperature extension |

By adding an electric heater, expand the temperature range from -25 ℃ to 80 ℃ |

||||||

|

Model |

FLTZ-202 FLTZ-202W |

FLTZ-203 FLTZ-203W |

FLTZ-204 FLTZ-204W |

FLTZ-206 FLTZ-206W |

FLTZ-208 FLTZ-208W |

FLTZ-210 FLTZ-210W |

FLTZ-215 FLTZ-215W |

|

Temp Range |

-25℃~90℃ |

||||||

|

Temp Control Accuracy |

±0.05℃ |

||||||

|

Flow Control |

10~25L/min ±0.3 |

15~45L/min ±0.3 |

25~75L/min ±0.3 |

||||

|

The flow control is adjusted by a frequency converter, and the maximum pressure of the circulation pump is 5bar. |

|||||||

|

Refrigeration @-15℃ |

2kw |

3kw |

3.8kw |

6kw |

7.6kw |

10kw |

15kw |

|

Internal Circulation Fluid Volume |

4L |

5L |

6L |

8L |

10L |

12L |

20L |

|

Expansion tank volume |

10L |

10L |

15L |

15L |

20L |

25L |

35L |

|

refrigerant |

R404A |

||||||

|

Secondary Refrigerant |

Silicone oil, fluorinated liquid, ethylene glycol aqueous solution, etc. |

||||||

|

Ingress and egress interface |

ZG1/2 |

ZG1/2 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG1 |

ZG1 |

|

Cooling water connection |

ZG1/2 |

ZG1/2 |

ZG3/4 |

ZG3/4 |

ZG1 |

ZG1 |

ZG1 1/8 |

|

Cooling water flow@20℃ |

1.2m³/H |

1.6m³/H |

2.6m³/H |

3.6m³/H |

5.5m³/H |

7m³/H |

10.2m³/H |

|

Power 380V |

3KW |

4KW |

6KW |

8KW |

9KW |

13KW |

17KW |

|

Temp Expansion |

By adding an electric heater, it can be extended to -25℃~80℃ |

||||||

|

Model |

FLTZ-402FLTZ-402W | FLTZ-403FLTZ-403W | FLTZ-404FLTZ-404W | FLTZ-406FLTZ-406W | FLTZ-408FLTZ-408W | FLTZ-410FLTZ-410W | FLTZ-415FLTZ-415W |

|

Temp Control |

-45℃~90℃ | ||||||

|

Temp control accuracy |

±0.05℃ |

||||||

|

Flow Control |

10~25L/min 5bar max |

15~45L/min 6bar max |

25~75L/min 6bar max |

||||

|

Heating |

Compressor heating is used to prevent condenser frosting technology |

||||||

|

Refrigeration Capacity @-35℃ |

1kw |

1.4kw |

1.8kw |

2.5kw |

3.3kw |

5kw |

8kw |

|

Internal circulation fluid volume |

4L |

5L |

6L |

8L |

10L |

12L |

20L |

|

Expansion tank volume |

10L |

10L |

15L |

15L |

20L |

25L |

35L |

|

Refrigerant |

R404A |

||||||

|

Secondary Refrigerant |

Silicone oil, fluorinated liquid, ethylene glycol aqueous solution, etc. |

||||||

|

Ingress and egress interface |

ZG1/2 |

ZG1/2 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG1 |

ZG3/4 |

|

Cooling water connection |

ZG1/2 |

ZG3/4 |

ZG3/4 |

ZG1 |

ZG1 |

ZG1 |

ZG1 1/8 |

|

Cooling water flow @20℃ |

1.5m³/H |

2.4m³/H |

3.5m³/H |

5m³/H |

5.5m³/H |

6m³/H |

8m³/H |

|

Power 380V |

3KW |

4KW |

6KW |

7.5KW |

9KW |

12KW |

15KW |

|

Temperature Expansion |

By adding an electric heater, it can be extended to -25℃~80℃ |

||||||

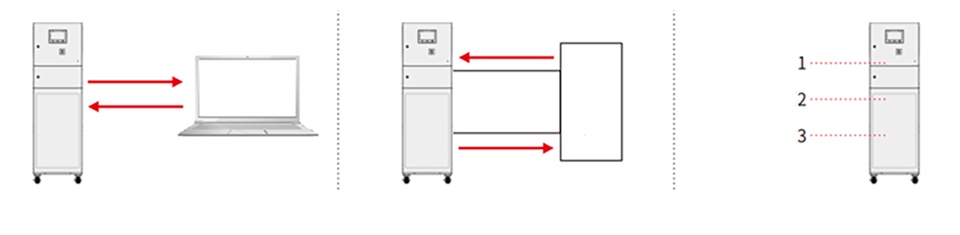

Communication function

Standard equipment includes serial

Communication (RS232C, RS485) and contact input/output. Can communicate with customer devices or build systems.

client output signal

recommend products

FLT-100℃~90℃ low temperature cascade

Product data downloadConfiguration Detailschillers that control the processing temperature on the Fab equipmentsApplicationsrecommend products Model FLTZ-803W FLTZ-805W FLTZ-806W FLT-Z808W FLTZ-810W Temp Range -80℃~+90℃ …

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -