Search the whole station

SOLUTION

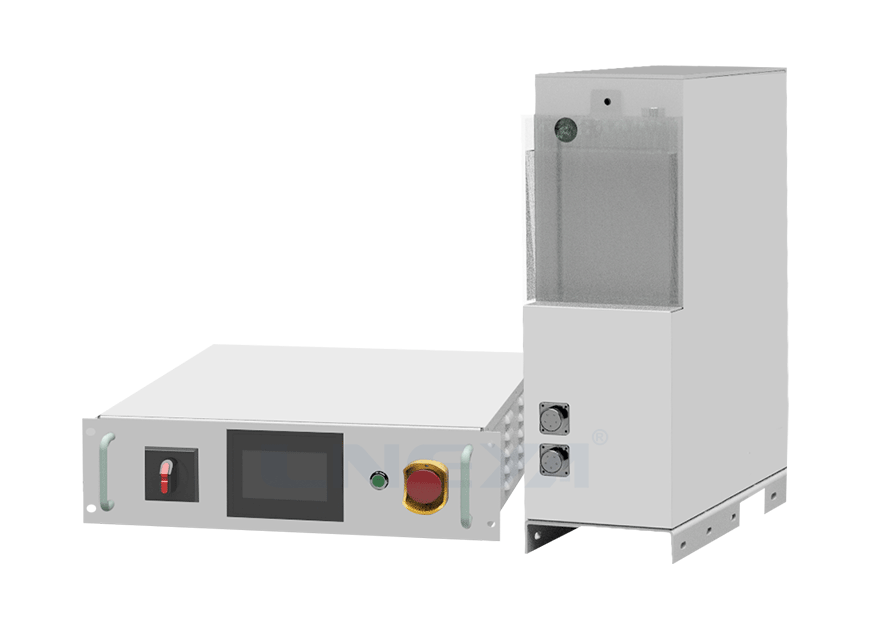

FLTZ Variable Frequency Chiller

—Temperature control accuracy ±0.05℃ (Outlet temperature steady state)

-90~+100℃, mainly used for precise temperature control in semiconductor production and testing processes. The company applies a variety of algorithms in the system to achieve fast system response and high control accuracy.

Dual channel chillers

—Precise temperature control for multiple fluid channels

FLTZ series dual-channel Chillers are mainly used for precise control of reaction chamber temperature in semiconductor manufacturing processes. The company applies multiple algorithms (PID, feedforward PID, model-free self-building tree algorithm) in the system to significantly improve the system’s response speed, control accuracy and stability.

Three channel chillers

—Triple channel chiller independent intelligent control

FLTZ series three-channel chillers are primarily used for precise temperature control during semiconductor production and testing. The system supports independent temperature control of three channels, each with its own temperature range, cooling and heating capabilities, and thermal medium flow rate.

Thermoelectric Peltier Chiller

—TEMPERATURE ACCURACY ±0.1℃

Dynamic temperature control of the electrostatic chuck (ESC) enables its application in all types of etching processes.

Fast and precise temperature control meets the most demanding process requirements.

Chiller Heat Exchange Series

—No compressor is used

Adopting ETCU compressor-free heat exchange system, the system can be universal expansion tank, condenser, cooling water system, etc., which can effectively reduce the size of equipment and reduce the number of operating steps.

Precision Air Conditioner

—Constant temperature and humidity unit

The equipment, production processes, inspection procedures, and spaces used in manufacturing facilities for semiconductors, liquid crystal displays, and solar panels require highly accurate and stable air handling. LWM series precision air conditioning units eliminate the high costs of area-wide air handling and maintenance.