HIGHLY TEMPERATURE CONTROL SYSTEMS

SUNDI Z Frequency Conversion Series

-80℃~250℃- Cooling capacity0.4kW~60kW

- Heating Power3.5kW~60kW

- RefrigerantR404A/R507C/R508B

- Weight115KG~300KG

Air-cooling & Water-cooling

DETAIL ADVANTAGE,STRIVING FOR EXCELLENCE

Configuration Details

| Model | SUNDIZ4-3 | SUNDIZ4-5 | SUNDIZ4-10 | SUNDIZ4-15W | SUNDIZ4-20W | SUNDIZ4-30W | |

| SUNDIZ4-3W | SUNDIZ4-5W | SUNDIZ4-10W | |||||

| Temperature range | -45℃~+250℃ | ||||||

| Heating power kW | 5.5 | 7.5 | 15 | 25 | 38 | 60 | |

| Cooling capacity kW @ | 250℃ | 5.5 | 7.5 | 15 | 25 | 38 | 60 |

| 20℃ | 5.5 | 7.5 | 15 | 25 | 38 | 60 | |

| -15℃ | 2.3 | 3.6 | 7.5 | 11 | 15 | 33 | |

| -35℃ | 0.9 | 1.5 | 3.3 | 5 | 6.5 | 10 | |

| Medium temperature control accuracy | ±0.1℃ | ±0.1℃ | ±0.1℃ | ±0.1℃ | ±0.1℃ | ±0.1℃ | |

| Process temperature control accuracy | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | |

| Pump flow & pressure max |

50L/min | 50L/min | 100L/min | 150L/min | 250L/min | 400L/min | |

| 2bar | 2bar | 2bar | 2.5bar | 2.5bar | 2.5bar | ||

| Interface size | G3/4 | G3/4 | G1 | DN32 PN10 | DN40 PN10 | DN50 PN10 | |

| Power supply | 380V 50HZ / 460V 60HZ | ||||||

| Model | SUNDIZ8-3W | SUNDIZ8-4W | SUNDIZ8-6W | SUNDIZ8-10W | SUNDIZ8-15W | |

| Temperature range | -80℃~+250℃ | |||||

| Heating power kW | 3.5 | 5.5 | 7.5 | 10 | 15 | |

| Cooling capacity kW @ | 250℃ | 3.5 | 5.5 | 7.5 | 15 | 20 |

| 20℃ | 3.5 | 5.5 | 7.5 | 15 | 20 | |

| -60℃ | 1.3 | 1.8 | 3 | 5.5 | 8 | |

| -75℃ | 0.4 | 0.6 | 1 | 1.8 | 2.7 | |

| Medium temperature control accuracy | ±0.1℃ | ±0.1℃ | ±0.1℃ | ±0.1℃ | ±0.1℃ | |

| Process temperature control accuracy | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | ±0.3℃ | |

| Pump flow & pressure max |

35L/min | 50L/min | 100L/min | 150L/min | 250L/min | |

| 2bar | 2bar | 2bar | 2.5bar | 2.5bar | ||

| Refrigerant | Primary R-404A + Secondary R508B | |||||

| Interface size | G3/4 | G3/4 | G1 | DN32 PN10 | DN40 PN10 | |

| Power supply | 380V 50HZ / 460V 60HZ | |||||

| System pressure display | The pressure of the refrigeration system and circulation system is detected by pressure sensors and displayed on the touch screen. | |||||

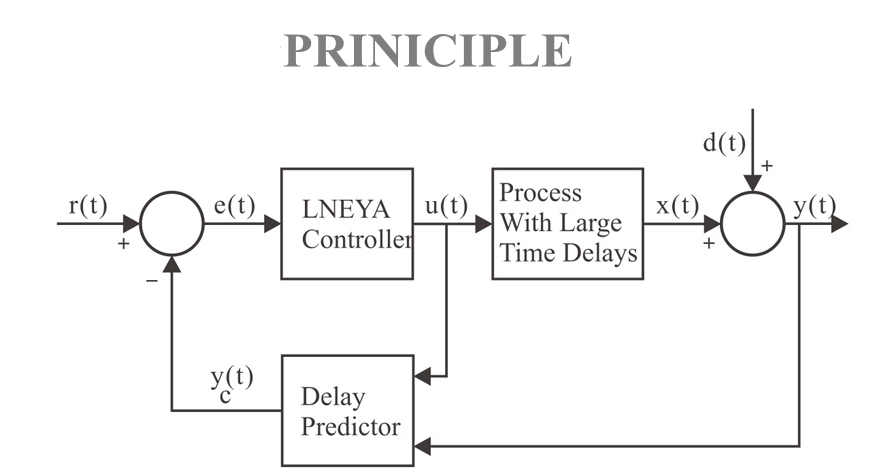

| Controller | Siemens S7-1200PLC, fuzzy PID control algorithm, with process dynamic control algorithm | |||||

| Temperature control | Heat transfer medium outlet temperature control mode | |||||

| External temperature sensor: (PT100 or 4-20mA or communication setting) Control mode (process dynamic control algorithm) |

||||||

| Programmable | 25 programs can be knitted, each program can be edited with 85 steps | |||||

| Communication Protocol | Ethernet interface TCP/IP protocol, RS485 interface MODBUS protocol | |||||

| Internal temperature feedback | Equipment heat transfer medium outlet temperature, medium inlet temperature, refrigeration system condensation temperature, ambient temperature, compressor suction temperature, cooling water temperature (for water cooling equipment) | |||||

| External temperature feedback | PT100 or 4~20mA or communication setting | |||||

| Cascade control | The temperature difference between the thermal oil outlet temperature and the external temperature sensor can be set and controlled | |||||

| Temperature difference control function | The temperature difference between the equipment inlet temperature and the outlet temperature can be set and controlled (to protect system safety) | |||||

| Closed circulation system | The entire system is a fully enclosed system. There will be no oil mist at high temperatures and no absorption of moisture in the air at low temperatures. The system will not increase pressure due to high temperatures during operation, and will automatically replenish heat transfer media at low temperatures. | |||||

| Heating | Refers to the maximum heating output power of the system (depending on the model) | |||||

| The heater has triple protection and independent temperature limiter to ensure the safety of the heating system | ||||||

| Use a voltage regulator to control the heating output and reduce the heater output current in process temperature control | ||||||

| Cooling | It refers to the ability to take away heat at different temperatures (under ideal conditions). The actual working conditions need to consider the heat dissipation of the environment. Please enlarge it appropriately and take insulation measures. | |||||

| External circulation pump flow & pressure | Brand magnetic drive variable frequency pump | |||||

| compressor | Emerson, Mitsubishi and other inverter compressors | |||||

| Frequency converter | ABB and other well-known brands | |||||

| Evaporator | 316L plate heat exchanger | |||||

| Refrigeration accessories | Danfoss/Emerson accessories (drying filter, oil separator, high and low pressure protector, expansion valve) | |||||

| Operation panel | Wuxi Guanya customized 7-inch color touch screen, temperature curve display, EXCEL data export | |||||

| Safety protection | It has self-diagnosis function; phase sequence failure protector, refrigerator overload protection, overload relay, thermal protection device and other safety protection functions. | |||||

| Refrigerant | R-404A / R507C Optional R448 | |||||

| Water cooled condenser | Standard plate heat exchanger | |||||

| Casing material | Cold rolled steel plate spraying (standard color RaL7035) | |||||

Ultra high temperature cooling technology can directly cool from a high temperature of 300℃[because only the heat transfer medium in the expansion chamber contacts with oxygen in the air (and the temperature of the expansion tank is between normal temperature and 60℃), which can reduce the risk of heat transfer medium being oxidized and absorbing water in the air. At high temperature, no heat conducting medium evaporates, and continuous temperature control of – 80℃ ~ 190℃, – 70℃ ~ 220℃, – 88℃ ~ 170℃, – 55℃ ~ 250℃ and – 30℃ ~ 300℃ can be realized without pressurization.

FLUID CIRCULATION CLOSED TEMPERATURE CONTROL

The fully enclosed pipeline design and high-efficiency plate heat exchanger reduce the demand for thermal fluid while improving the system’s heat utilization rate and achieving rapid temperature rise and fall. The thermal medium is in a closed system with an expansion container. The thermal medium in the expansion container does not participate in the circulation. Regardless of high or low temperatures, the expansion tank temperature is kept at room temperature to 60°C, effectively reducing the risk of the thermal medium absorbing moisture and volatilizing during operation.

WIDE RANGE OF APPLICATION INDUSTRY SERVICES

Application: Various Reactors (Microchannels, Glass, Jacketed Reactors, etc.), Distillation or Extraction System, Laboratory, University, Research Institute, Aerospace, Automotive Industry, Semiconductor and Electrical Test, Chemical, Pharmaceutical, Petrochemical, Biochemical, Medical, Hospital, R&D Workshop, Aerospace, Biological and Other Industries.

APPEARANCE DETAILS OUALITY CONTROL

You may also be interested in these products

SUNDI -10℃~150℃

Product data downloadMaterial temperature and equipment outlet temperature control optionalDynamic Cooling Heating SystemControl temperatureTemperature AccuracyConfiguration DetailsWorking PrincipleYou may also be interested in these products …

SUNDI -45℃~300℃

ProductDescriptionConfiguration DetailsWorking PrincipleDisplays Various Information:You may also be interested in these products ● Working temperatures from -120°C to +350°C● Previously unachievable performance●Intelligent…

SUNDI -80℃~250℃

Product data downloadProductDescriptionConfiguration DetailsWorking PrincipleYou may also be interested in these products ● Working temperatures from -120°C to +350°C● Previously unachievable performance●Intelligent temperature…

SUNDI-320/420W/430W

Product data downloadMaterial temperature and equipment outlet temperature control optionalDynamic Cooling Heating SystemControl temperatureTemperature AccuracyConfiguration DetailsProductDescriptionprincipleApplicationsFor pilot production/experi…

SUNDI -25℃~200℃

Product data downloadMaterial temperature and equipment outlet temperature control optionalDynamic Cooling Heating SystemControl temperatureTemperature AccuracyConfiguration DetailsWorking PrincipleYou may also be interested in these products …

SUNDI -25℃~300℃

ProductDescriptionConfiguration DetailsWorking PrincipleDisplays Various Information:You may also be interested in these products ● Working temperatures from -120°C to +350°C● Previously unachievable performance●Intelligent tem…

SUNDI -45℃~250℃

Product data downloadProductDescriptionConfiguration DetailsWorking PrincipleDisplays Various Information:You may also be interested in these products ● Working temperatures from -120°C to +350°C● Previously unachievable perfor…

SUNDI -60℃~250℃

Product data downloadProductDescriptionConfiguration DetailsWorking PrincipleDisplays Various Information:You may also be interested in these products ● Working temperatures from -120°C to +350°C● Previously unachievable per…

SUNDI -70℃~250℃

Product data downloadProductDescriptionConfiguration DetailsWorking PrincipleDisplays Various Information:You also be interested in ● Working temperatures from -120°C to +350°C● Previously unachievable performance●Intelligent …

SUNDI -90℃~250℃

Product data downloadProductDescriptionConfiguration DetailsWorking PrincipleDisplays Various Information:You may also be interested in these products ● Working temperatures from -120°C to +350°C● Previously unachievable perfo…

SUNDI -100℃~135℃

Product data downloadProductDescriptionConfiguration DetailsWorking PrincipleYou may also be interested in these products ● Working temperatures from -120°C to +350°C● Previously unachievable performance●Intelligent temperature…

SUNDI -25℃~200℃ For Two Reactors

Product data downloadYou may also be interested in these products * ,

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -