Energy Storage System Battery Thermal Management & Chiller

CNYL 45kW- Cooling power45KW

- Temperture accuracy±0.5℃

- Control SystemPLC

- Power range380V 50HZ Choose 220V60HZ 460V 60HZ

Product data download

Parameters Detail

|

Model |

CNYL -45~55 |

|

Cooling Capacity |

45KW |

|

Temperature Control Accuracy |

±0.5℃ Real-time temperature record |

|

Secondary Refrigerant |

Ethylene glycol antifreeze, fully enclosed design of refrigerant circulation system |

|

Refrigerant |

R410A |

|

Flow |

300L/min~400L/min Set display history |

|

Pressure Sensor Detection |

Liquid outlet pressure, liquid inlet pressure, refrigeration system high and low pressure |

|

Temperature Sensor Detection |

Liquid outlet temperature, liquid inlet temperature, refrigeration system exhaust and suction temperature, condensation temperature |

|

Liquid Level of Expansion Tank |

Liquid level sensor real-time monitoring |

|

Heating |

Using compressor heating to prevent condenser frosting technology, the system has no PTC heater |

|

Energy Consumption Display |

The system has real-time energy consumption and cycle cumulative energy consumption display |

|

Condenser |

microchannel heat exchanger |

|

Evaporator |

Plate heat exchanger |

|

Cooling Throttling |

Electronic expansion valve |

|

Low Pressure electrical |

Schneider/Siemens |

|

Display Screen |

7 inch color touch screen |

|

Control System |

PLC |

|

Communication |

CAN |

|

Network |

Real-time operation and maintenance management of equipment through the Internet of Things platform |

|

Ambient use temperature |

-45℃~55℃ |

|

Safety Protection |

With self-diagnosis function, phase sequence and phase failure protection, safety voltage protection, abnormal flow protection, high and low pressure protection of refrigeration system, exhaust and suction temperature protection, high and low liquid level protection, abnormal circulation pipeline pressure protection |

|

Power |

380V 50HZ Choose 220V60HZ 460V 60HZ |

|

Shell Material |

Cold-rolled sheet spray REL7035 |

|

Internal Piping |

SUS304 |

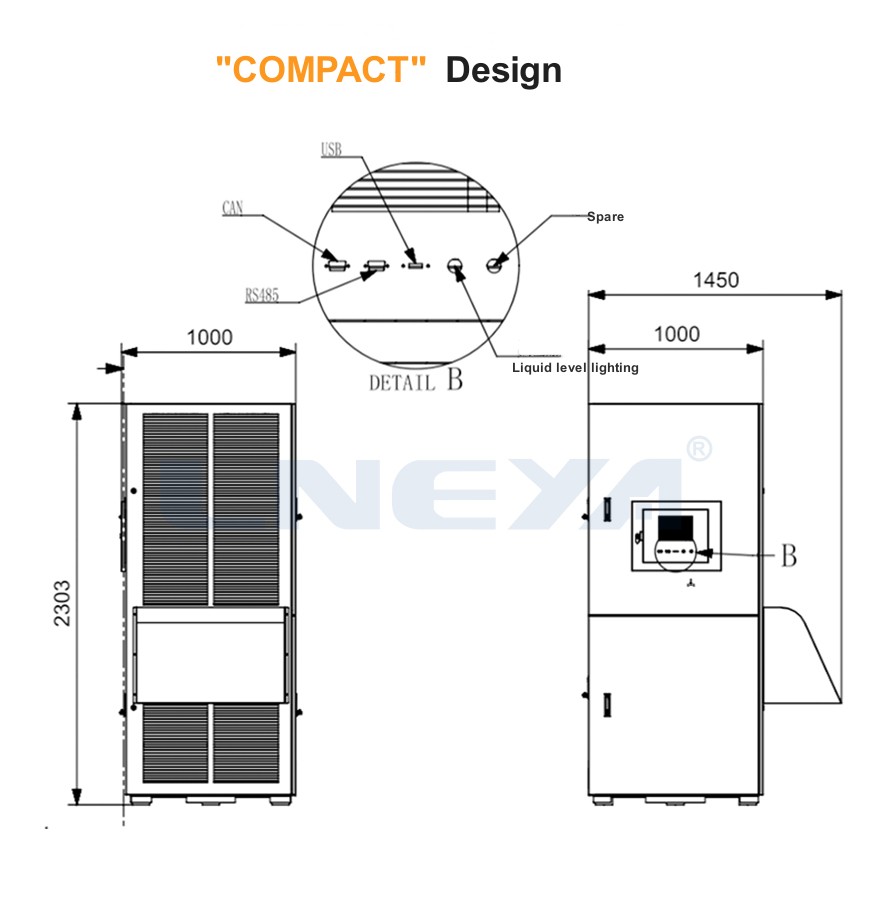

Product Description

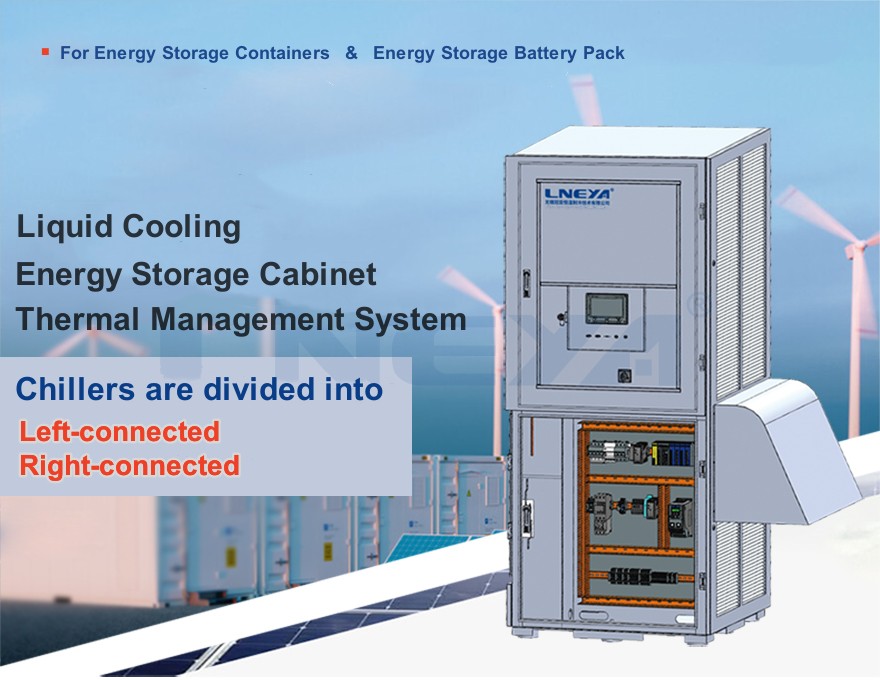

Battery Energy Storage Systems are filled with many battery cells, generating a large amount of extreme heat load. This means that the cooling system needs to precisely control the temperature and efficiently dissipate the large amount of heat generated by the battery charge and discharge cycle. Chillers are one of the most reliable liquid cooling systems and can alleviate many maintenance and service concerns.

Considering the high temperatures generated by battery charge and discharge cycles, it is clear that the most efficient solution is to install a recirculation cooler in the battery storage tank. LNEYA’s chillers also feature precise temperature control. LNEYA’s design engineers rely on decades of experience to shape and size chillers to reliably conform to and withstand climate change and extreme conditions without taking up too much valuable space in battery energy storage.

Efficient “nanny-style” temperature control and intelligent linkage with battery temperature

Ambient operating temperature range -45°C~55°C

Can be used below 3000 meters above sea level

Protection above IP50 can meet anti-corrosion requirements

Intelligent, multilingual color touch screen provides clear and comprehensive important data information

Real-time display of flow pressure data

Fully enclosed design of ethylene glycol antifreeze circulation system

Using compressor heating to prevent condenser frosting technology, the system has no PTC heater

Real-time operation and maintenance management of equipment through the Internet of Things platform

Suitable for single high current liquid cooling test

Complement the existing liquid cooling circulation channel, single channel, air cooling

Applicable to energy storage modules, energy storage sub-box performance test

Suitable for performance testing of vehicle power supply products

Applicable to vehicle power supply large module, energy storage module, energy storage plug-in box test, suitable for vehicle power supply product performance test

Applicable to energy storage modules, energy storage sub-box performance test

Applicable to cycle test, the cooling method is liquid cooling mode

Applicable to cycle test, the cooling method is liquid cooling mode

Applicable to vehicle power supply, energy storage system test

Suitable for performance testing, the cooling method is liquid cooling mode

Applicable to vehicle power supply, energy storage system test

Suitable for performance testing of vehicle power supply products

Suitable for performance testing of R&D projects, prepared for cylindrical/other direct cooling projects

REQUEST A QUOTE

You may also be interested in these products

Liquid Cooling Chiller(Commercial Energy Storage)

Product data downloadParameters DetailProductDescriptionEfficient “nanny-style” temperature control and intelligent linkage with battery temperatureYou may also be interested in these products Battery Energy Storage Systems a…

Liquid Cooling Chiller(Charging Pile)

Product data downloadParameters DetailAdvantage Characteristics:You may also be interested in these products Model CHDYL-4 -45℃~55℃ Cooling Power 4KW Temp control accuracy ±1℃ Real-time temperature record Refrigerant Brine circ…

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -